When it comes time to execute a planning run in SAP Materials Management (SAP MM), you have two options: total planning or single-item planning.

However, before your planning run can be executed, all the required master data objects must be in place, and materials in scope must have planning file entries maintained.

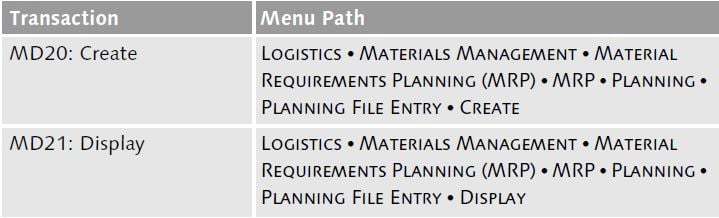

The table above lists related planning run transactions. Also, MRP must be active for the plant you want to run planning for, and MRP views must exist for materials at that plant. After all of these prerequisites are fulfilled, you can execute planning material requirements for materials with changed requirements or stock levels.

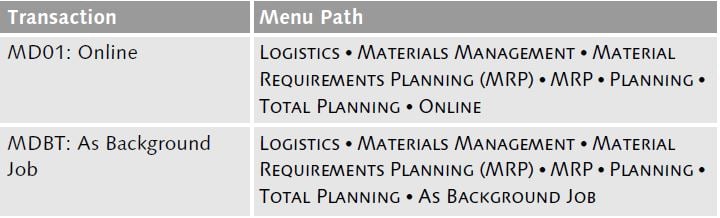

Total Planning

SAP provides you with an efficient method of executing planning for all materials within a planning plant, which is called regenerative planning. You can also choose to plan for materials with changes that occurred since the last planning run and are relevant and considered in the new planning run, which is called net change planning. You can also control the scope of the planning run by setting your selection parameters and execute your run for the following:

- One or more plants

- A single MRP area

- Multiple MRP areas

- Combinations of plant and MRP areas

Total planning is usually executed as a background job due to its massive scope and hunger for system resources. Use the parallel processing option whenever possible to speed up the execution time by spreading the workload to several sessions or servers.

You can influence materials selection for the total planning run by activating the user exit in enhancement M61X0001, which allows you to pull in materials based on additional criteria, such as MRP controller.

The next table lists two of the transaction codes relevant to this process and the corresponding menu paths.

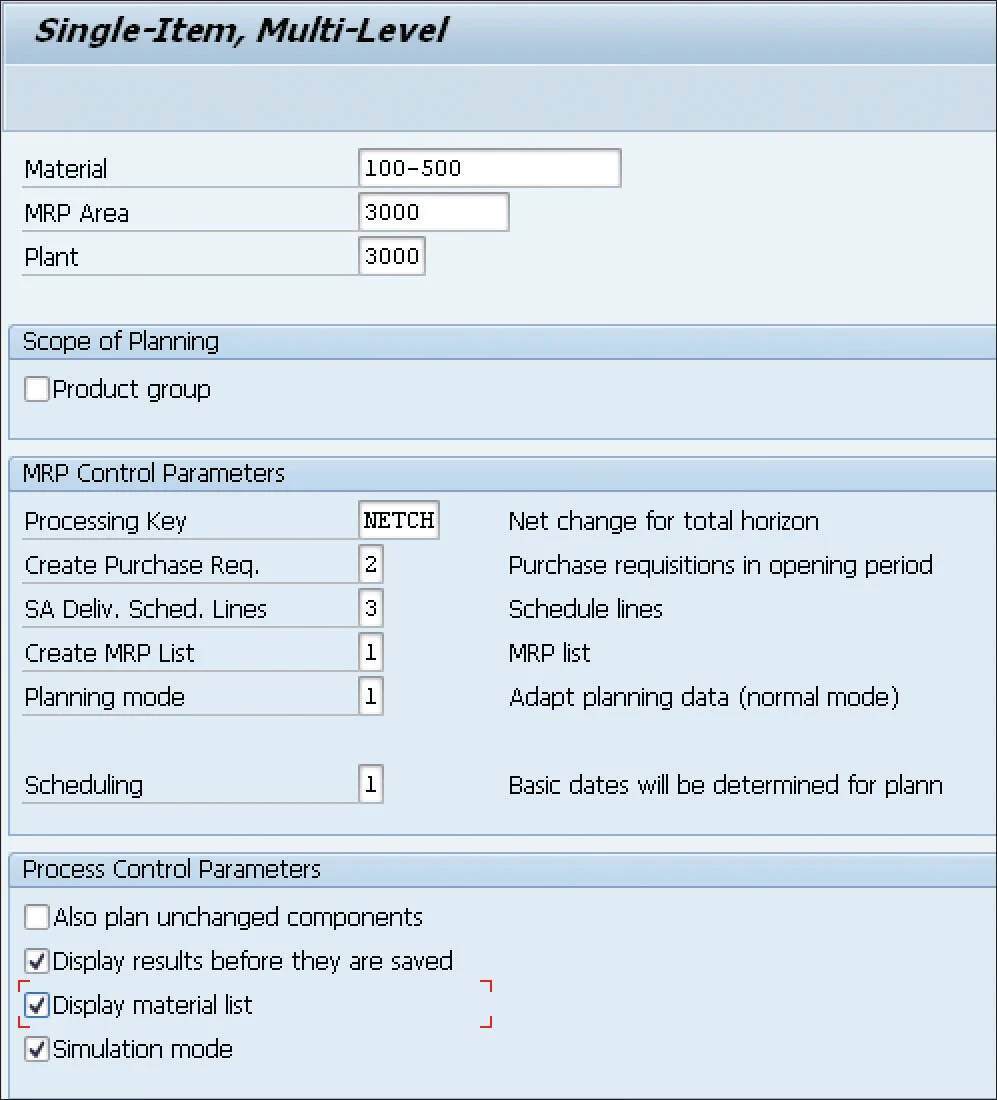

Single-Item Planning

In the previous section, we covered a mass-processing scenario. In this method, on the other hand, the single-item planning scope covers just one material. You’ll have two options to execute single-item planning:

- Single-item, with multilevel planning: All levels of the BOM are in scope of the planning run.

- Single-item, with single-level planning: One material is planned, and only if a planned order is created, is its BOM exploded, creating dependent requirements for the next level.

Let’s walk through an example of executing planning using Transaction MD02 (Single-Item, Multilevel Planning). The figure above shows examples of the selection options.

First, enter the Material, Plant, and MRP Area, if you’re using this type of planning. The Product group checkbox in the Scope of Planning section is usually left unselected unless you use product groups.

Then, specify the following MRP Control Parameters section fields to control how MRP data is used and modified:

- Processing Key: For example, enter “NETCH” which calculates net changes for the total horizon.

- Create Purchase Req.: Controls whether purchase requisitions or planned orders are created.

- SA Deliv. Sched. Lines: Controls whether and how the schedule lines are created for scheduling agreements.

- Create MRP List: Controls whether the list for MRP results is generated.

- Planning mode: Controls how you look at already existing planning data in the new MRP run.

- Scheduling: Controls how date calculations are performed for planned orders.

Set the Process Control Parameters that control the subsequent processing mode:

- Without an interactive check of the planning result, the Display results before they are saved option isn’t selected.

- With an interactive check of the planning result per material, you can display results before saving. The Display results before they are saved option has to be checked to enable it, and you can also review planning in simulation mode. All materials are planned in memory, without saving to the database, allowing you to test the planning run and apply corrections immediately before a final run and save.

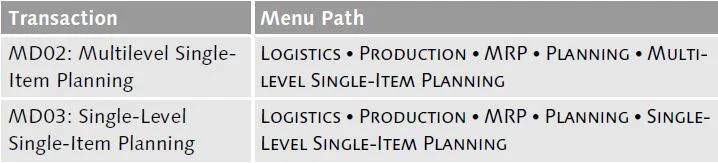

The final table lists the transactions for planning executing for individual materials—single items—in multilevel or single-level mode.

Conclusion

There are many influencing factors that drive planning behavior in SAP MM, from configuration to master data, from consumption-based planning and forecasting through SAP standard and flexible planning. We hope this blog post helps you fit the pieces together for executing a planning run.

Editor’s note: This post has been adapted from a section of the book Procurement with SAP MM: Business User Guide by Matt Chudy and Luis Castedo.

Comments