The main objective of MRP is to provide an accurate picture of material availability.

The result of an MRP run depends on how key master data for in-house production and externally purchased items (e.g., MRP type, MRP procedure, lot size, and quota arrangement) are maintained. In this post, we’ll discuss several updates and simplifications to material master attributes on MRP views in SAP S/4HANA.

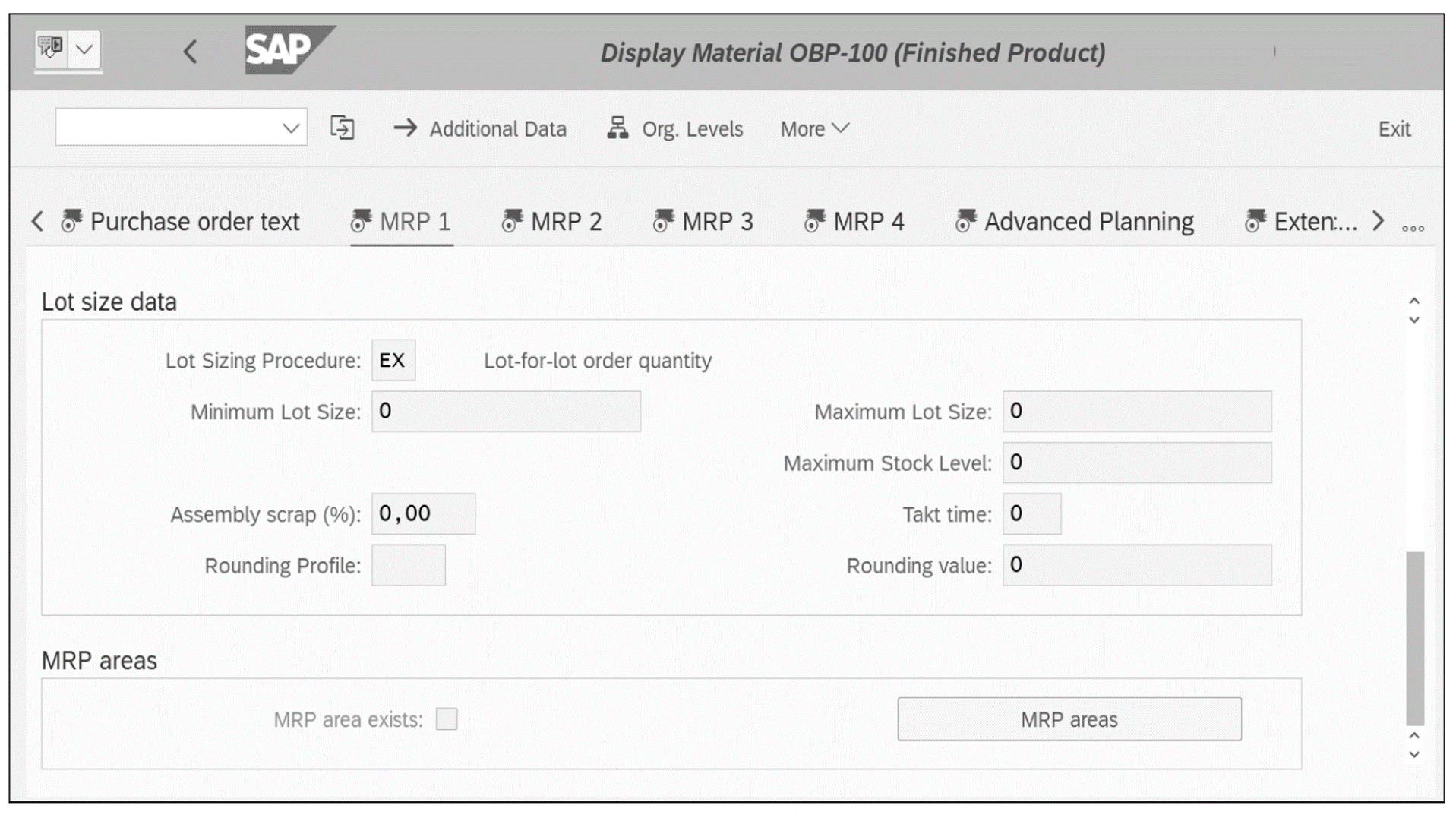

The first change is on the MRP 1 tab, from which the Lot Size Unit of Measure group has been removed. (Within the retail industry set, this functionality is still enabled.)

In SAP S/4HANA, the MRP areas settings, shown at the bottom of the figure below, cover business requirements and can exclude certain storage locations during an MRP run. The MRP area also allows users to utilize all MRP types and lot-sizing procedures in the material master’s MRP 1 tab.

Moreover, planning files are created on both the plant level and the MRP area level. If planning is required on the MRP area level, then the system plans only the affected MRP areas. This way, planning on the MRP area level is more efficient when a plant has multiple offsite locations. The MRP area helps with the subcontracting scenario, so it should be created for every subcontractor.

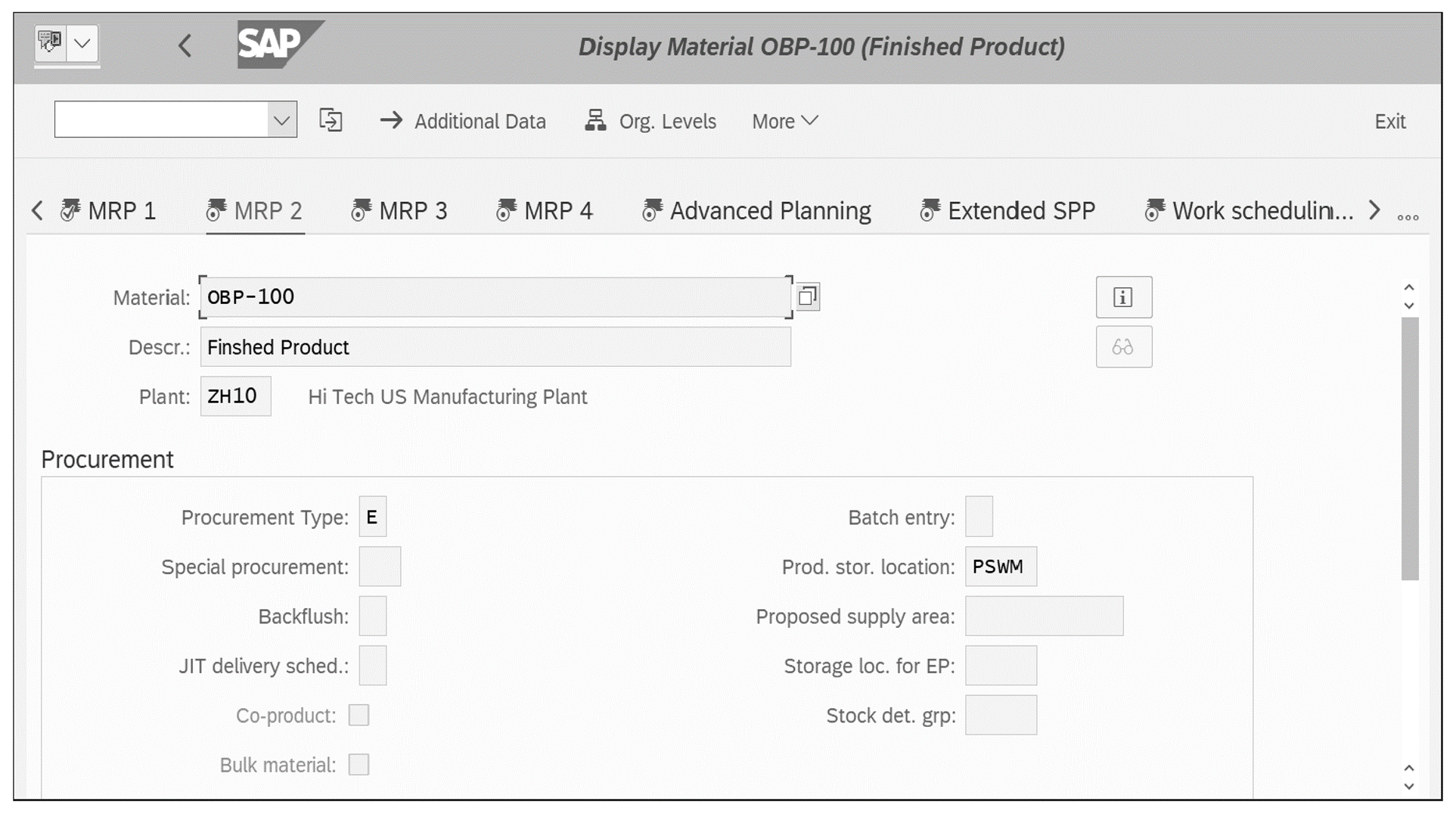

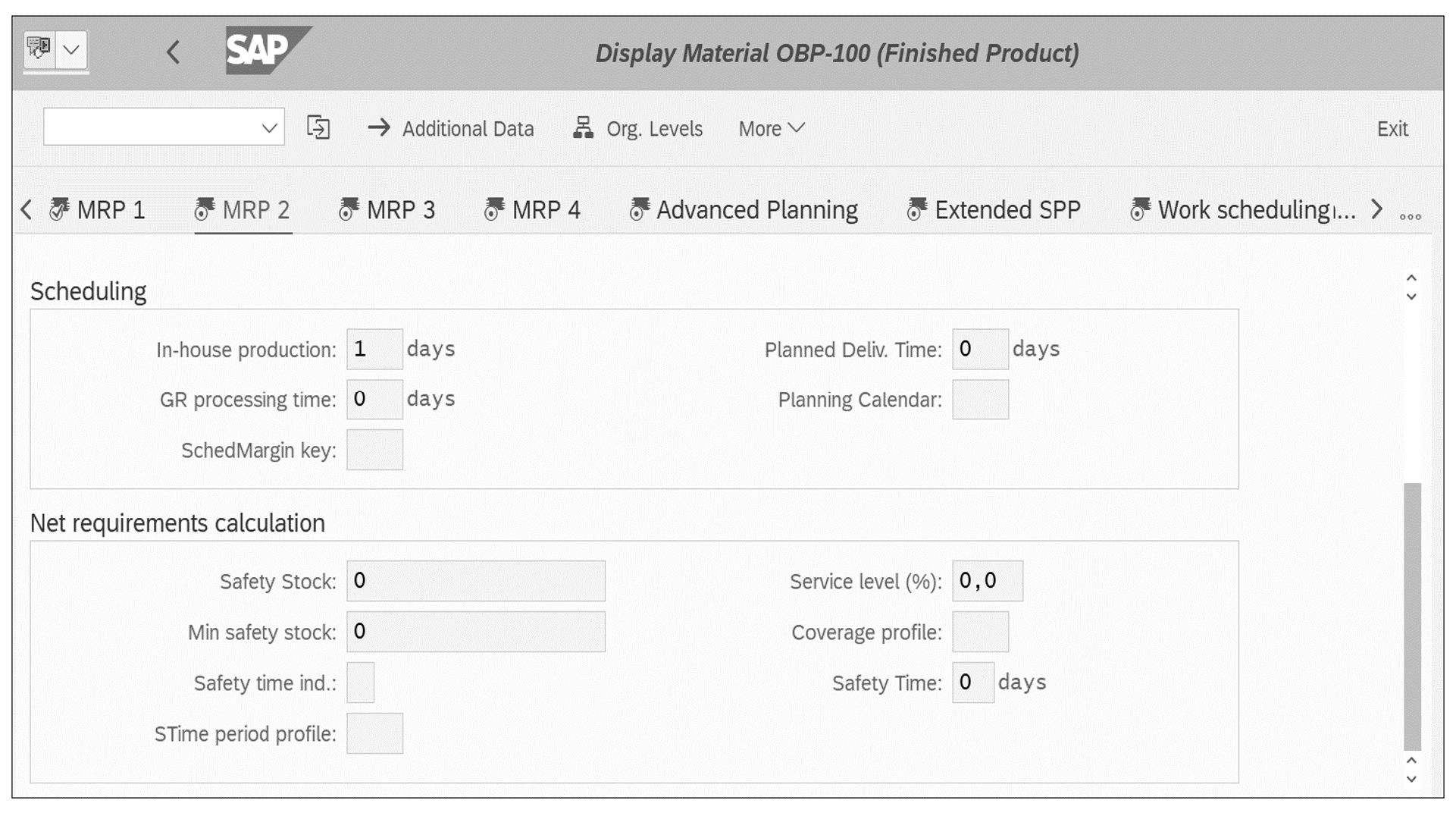

Quota arrangement is a way to find the right source of supply. Because MRP always considers quota arrangement, SAP S/4HANA logistics' capability has excluded the Quota Arrangement checkbox from the MRP 2 tab, shown in the figures below.

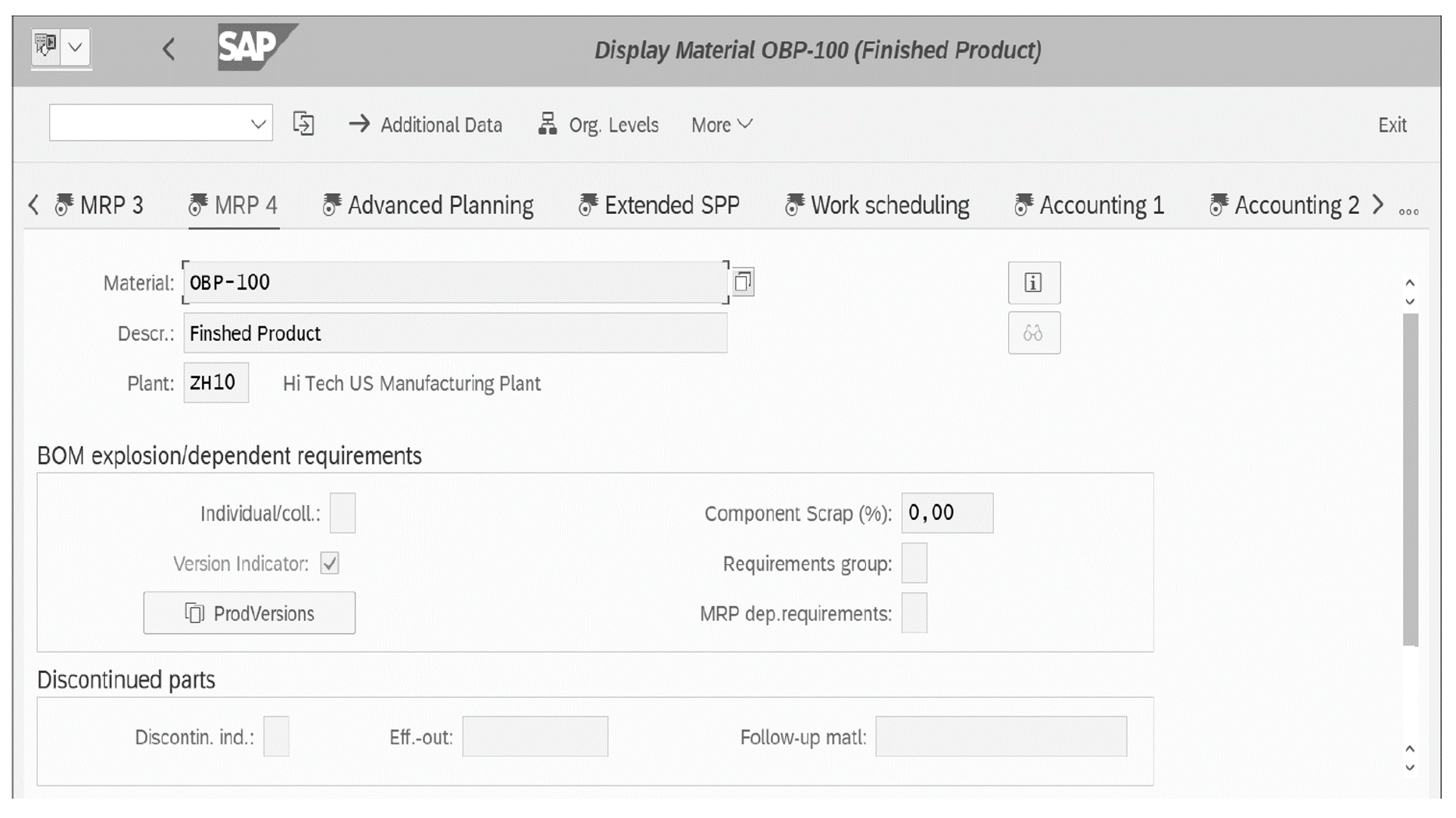

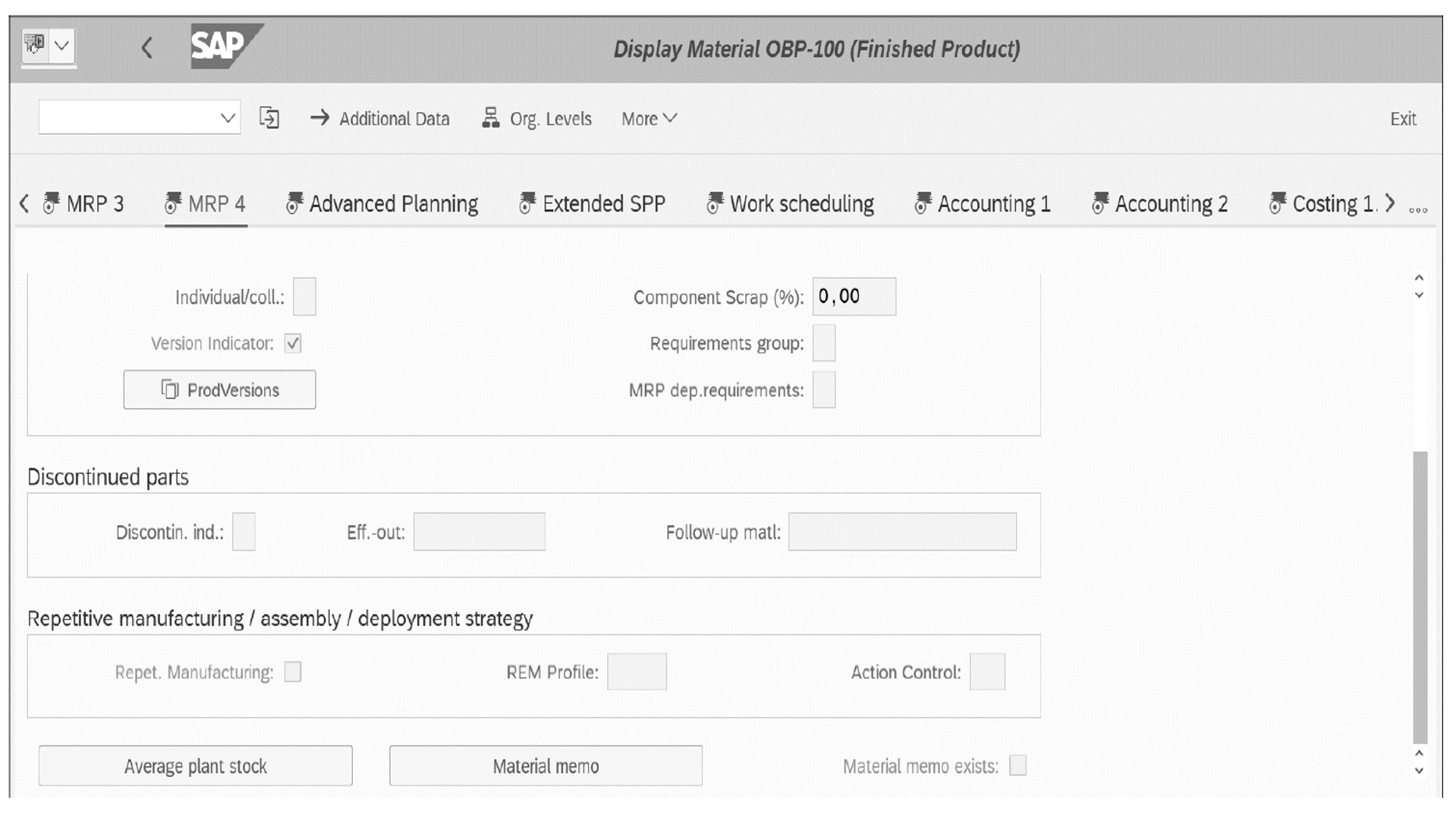

Furthermore, multiple changes have been applied to fields in the MRP 4 tab. The figure below shows that the action console, fair share rules, push distribution, deployment horizon, and selection method functionalities have been removed from the MRP 4 tab.

In addition, the Repetitive manufacturing/assembly/deployment strategy grouping has been added to the MRP view, as shown here.

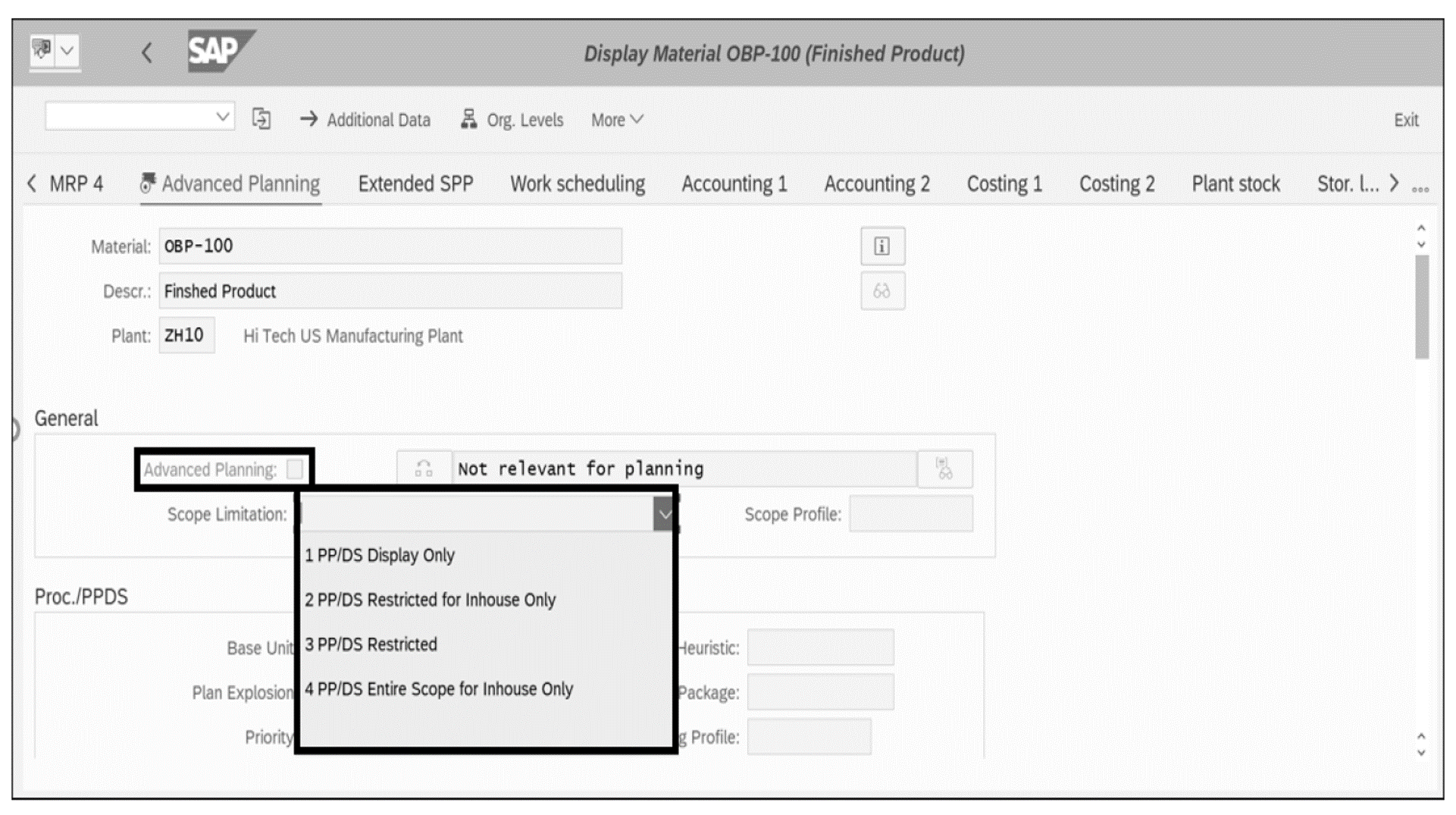

Another change has been made in the Advanced Planning view. Below shows that this view now includes the Advanced Planning indicator to specify that the material is relevant for PP-DS in SAP S/4HANA.

A new function has been introduced allowing you to limit actions that can be taken on planning objects in PP-DS based on the Scope Limitation value selected for the product locations in the material master. The available Scope Limitation values are as follows:

- PP/DS Display Only: Users cannot execute any functions on any planning objects either manually or automatically.

- PP/DS Restricted for Inhouse Only: Users can execute any create/update/delete functions on any in-house planning objects, such as planning, production, and process orders, manually or automatically using a positive list of heuristics, which are part of the Scope Profile.

- PP/DS Restricted: Users can execute any create/update/delete functions on any in-house or external procurement planning objects manually or automatically using a positive list of heuristics, which are a part of the Scope Profile. This limitation is mainly used in PPDS transactions to plan and schedule all planning objects with restrictions.

- PP/DS Entire Scope for Inhouse Only: Users can execute any create/update/delete functions on any planning objects manually and automatically (using a job or by running heuristics). Users cannot make any changes to external procurement objects.

- PP/DS Entire Scope: Users can execute all planning and scheduling activities manually and automatically, irrespective of the planning object.

Note: A blank value in Scope Limitation means that there are no limitations and the user can perform all activities on in-house and external planning objects.

Learn MRP in Our Rheinwerk Course!

It’s time to master MRP! This course guides participants through the steps of the MRP run, from setting up integral master data to configuring its outputs for optimized analysis. Explore advanced functions and the what-if scenario planning capabilities of SAP S/4HANA! Get access to course recordings by clicking the banner below.

Editor’s note: This post has been adapted from a section of the book Logistics with SAP S/4HANA: An Introduction by Deb Bhattacharjee, Vishal Khandalkar, Falguni Thompson, and Guillermo B. Vazquez. Deb is a Deloitte principal and partner a thought leader in supply chain strategy, supply chain planning, and inventory planning and management. Vishal is a senior technology transformation leader at Deloitte. Falguni is a managing director at Deloitte, where she is a leader in digital transformation within Deloitte’s Enterprise Performance offering. Guillermo is a senior technology executive, leading multimillion-dollar SAP global programs with Fortune 500 companies.

This post was originally published 4/2022.

Comments