Inventory in SAP can be classified across the entire supply chain by forms/flow of materials and by purposes/functions. This blog post will discuss classifying inventory by the flow of materials and by purpose.

It will also dive into specific details of the different SAP inventory types: cycle stock, pipeline stock, safety stock, merchandizing stock, and prebuild stock.

Flow of Materials and Purpose

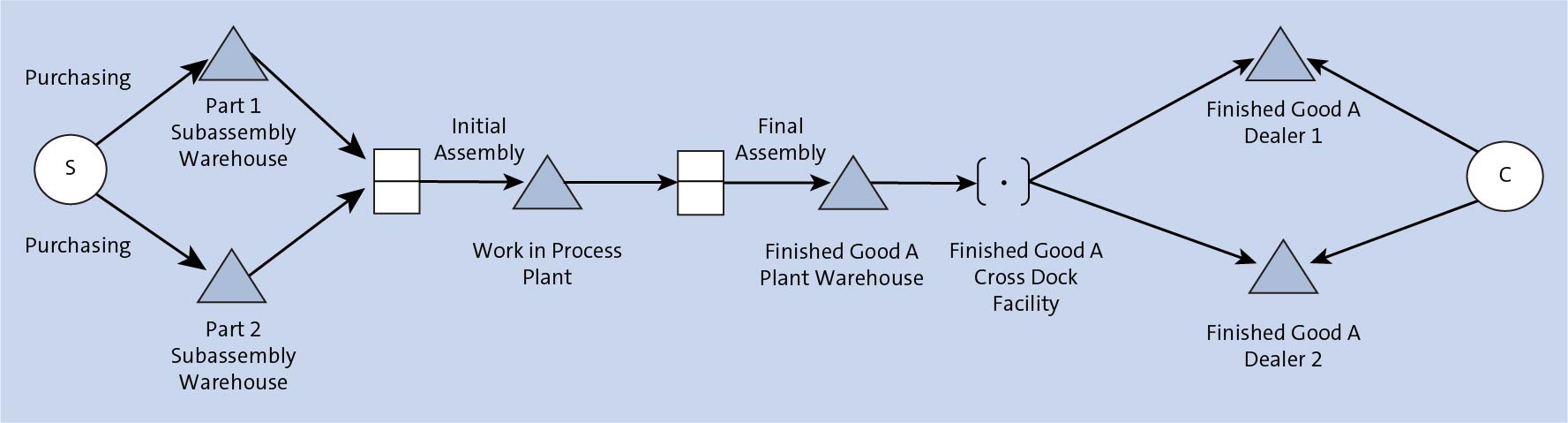

Inventory types can be grouped into four classifications by the flow of materials across the supply chain, as depicted in this figure:

Raw Materials

Raw materials are inventory items that are purchased but haven’t entered the production process. They include purchased materials, component parts, and subassemblies. Typically, raw materials are commodities such as ore, grain, minerals, petroleum, chemicals, paper, wood, paint, steel, and food items.

However, items such as nuts and bolts, ball bearings, key stock, casters, seats, wheels, and even engines may be regarded as raw materials if they are purchased from outside sources.

In most cases, raw materials are used in the manufacture of components. These components are then incorporated into the final product or become part of a subassembly. Subassemblies are then used to manufacture or assemble the final product.

Work in Process (WIP)

Work in process is made up of all the materials, components, assemblies, and subassemblies that have entered the manufacturing process and are being worked on or waiting to be worked on. This usually includes all materials, from raw materials that have been released for initial processing up to materials that have been completely processed and are awaiting final inspection and acceptance before inclusion in finished goods.

Finished Goods

Finished goods are the finished products of the production process that are ready to be sold as completed items. These goods have passed final inspection requirements so that they can be transferred out of work in process and into finished goods inventory.

From this point, finished goods can be sold directly to their final users, sold to retailers, sold to wholesalers, sent to distribution centers, or held in anticipation of a customer order.

Maintenance, Repair, and Operating Supplies

Maintenance, repair and operating supplies (MROs) are inventory items that are used in production but do not become part of a product. MRO items may include consumables (e.g., cleaning supplies), industrial equipment (e.g., valves, compressors, and pumps) and plant upkeep supplies (e.g., gaskets, lubricants, and repair tools), as well as computers, furniture, and so on.

The figure above showed an example of a flow of materials that includes movement of goods from supplier to consumer and transformation between different types of inventory.

SAP Inventory Types

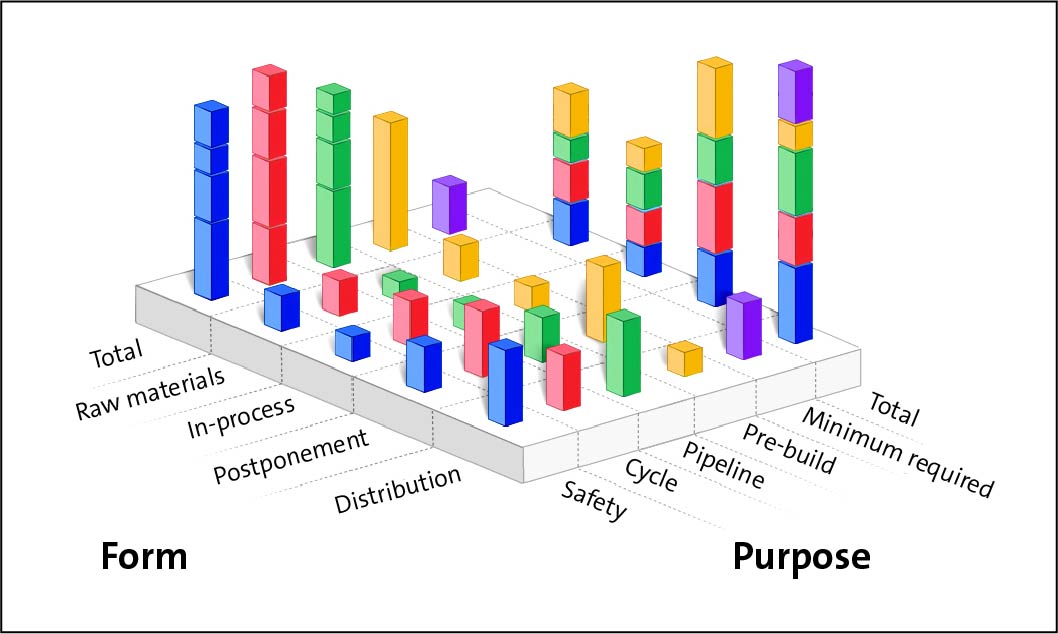

Inventory can also be classified according to the purpose it serves. These inventory types may include the following:

- Cycle stock: Inventory needed to meet current demand until the next order can be placed

- Pipeline stock: Inventory needed to meet future demand until the next order can be received

- Safety stock: Inventory needed to hedge against risk and uncertainty

- Merchandizing stock: Additional “display” stock needed on hand in each period

- Prebuild stock: Inventory that ensures against predictable demand variability

Note that prebuild stock can be modeled and calculated by SAP Integrated Business Planning (SAP IBP) for response and supply. Except for prebuild stock, SAP IBP for inventory provides complete visibility into all other components of inventory based on inventory forms and purposes across the entire supply chain network and planning horizon (as shown in the figure below).

The multiechelon inventory model in SAP IBP for inventory allows multiple types of inventory, including cycle stock, pipeline stock, and merchandising stock, along with safety stock, to be properly modeled across the supply chain. This opens tremendous opportunities to improve supply chain performance and lower total inventory.

In the following sections, we’ll elaborate more on the five types of inventory classified by their purposes and explain the drivers of each one.

Cycle Stock

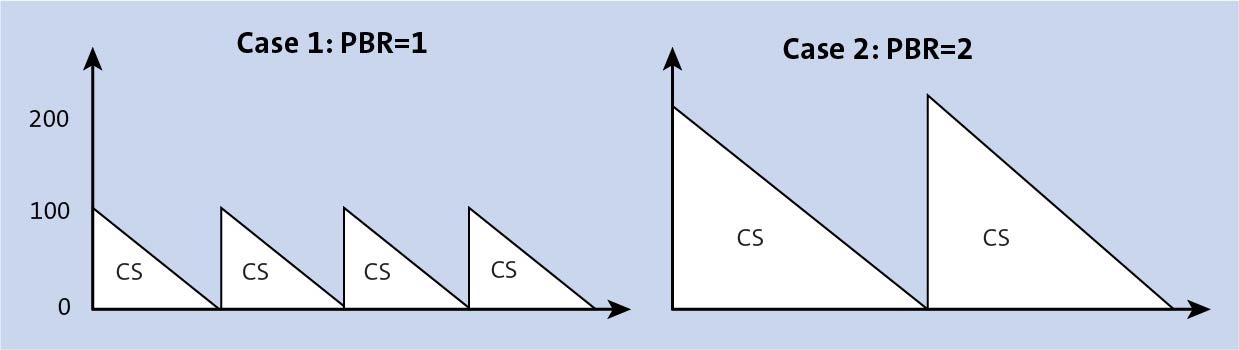

Cycle stock is the amount of inventory that is planned to be used to meet current demand during a period until the next order can be placed. This time is often defined as periods between review (PBR). It’s either the time between orders (for raw materials) or the time between production cycles (for work in process and finished goods). The quantity of cycle stock inventory is equal to the total on-hand inventory minus the safety stock inventory.

Key drivers of cycle stock are demand forecast, replenishment frequency, and lot sizes. For example, cycle stock increases with PBR, as shown here:

Cycle stock inventory serves an important function in a company’s accounting. As a business sells its cycle stock inventory and replenishes it, its cash flow accounts for the income it receives and the payments it makes. Cycle stock inventory is also part of a company’s total assets on its balance sheet. To determine the cost of cycle stock inventory, a business can use the last-in, first-out method or the first-in, first-out method, which base the price of items in the cycle stock on the most recent or oldest prices paid, respectively.

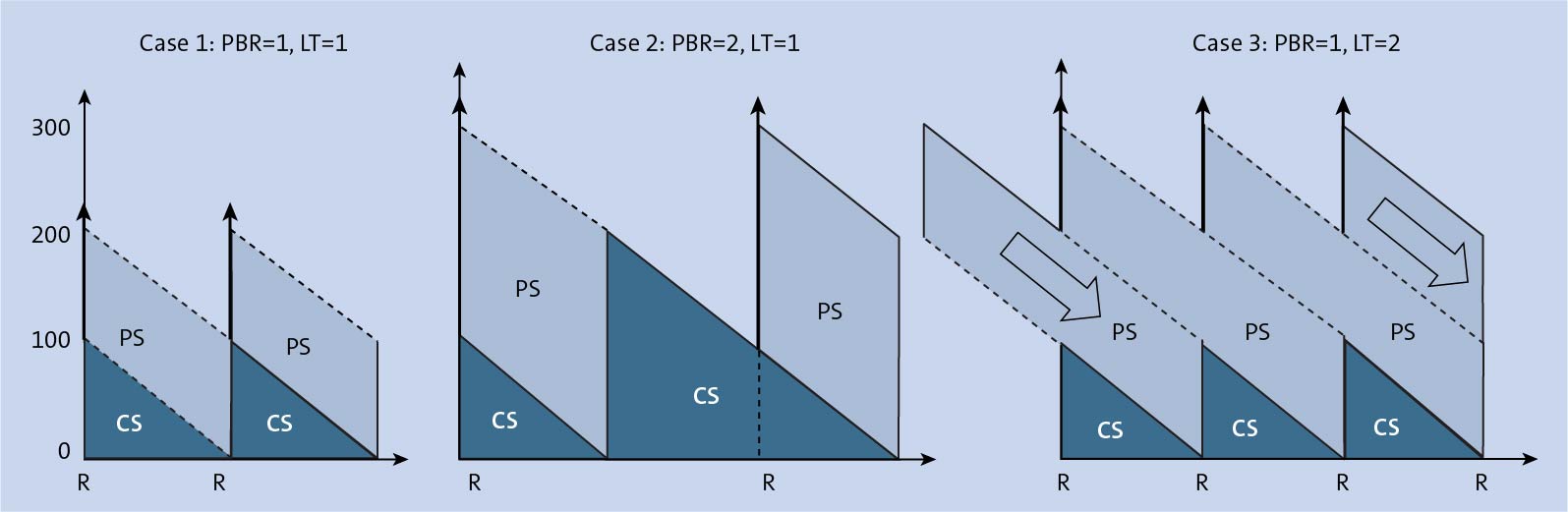

Pipeline Stock

Pipeline stock is in-transit stock that is planned to be used to meet future demand. For example, pipeline stock consists of items that are in the transit pipeline between locations, such as those en route from the warehouse to the retail outlet.

While the items are in transit, they are still considered to be part of the shipper’s inventory if the recipient has yet to pay for them. When the recipient pays for the items, even if that recipient has not taken physical custody of the items, that pipeline inventory goes on the recipient’s inventory list.

Key drivers of pipeline stock are demand forecast and production or transportation lead time. Pipeline stock should cover the total planned receipts of all periods during the lead time. Therefore, pipeline stock increases with lead time as shown below.

Safety Stock

Safety stock is the buffer used to hedge against risk and uncertainty, such as loss of production due to plant shutdown, late deliveries, or unexpectedly high demand. Learn more about safety stock in SAP here.

Merchandizing Stock

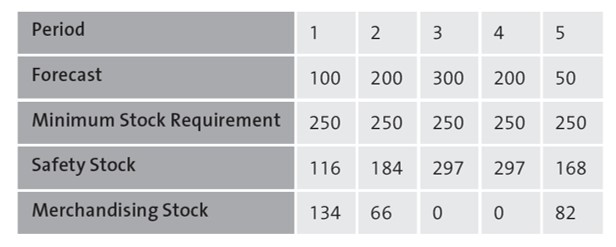

Merchandizing refers to the variety of products available for sale and displaying those products in such a way as to stimulate interest and entice customers to make a purchase. In SAP IBP for inventory, merchandizing stock is calculated as the difference between the minimum stock requirement and safety stock in each period.

Therefore the merchandizing stock reflects additional display stock needed on-hand in that period. The table below illustrates how merchandising stock is calculated given safety stock and minimum stock requirements.

Prebuild Stock

Prebuild stock is the amount of inventory built due to capacity constraints in anticipation of future demand. Prebuild stock is needed when a demand for a given period exceeds capacity. If this occasion arises, additional inventory in the previous period(s) must be produced or stored in anticipation of the period with a demand higher than maximum capacity.

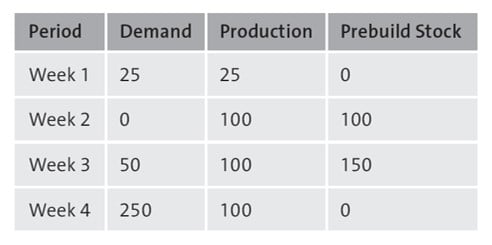

In the following example, let’s assume the maximum production capacity of a product is 100 units per week. The demand for this product as per each week in January is given in the next table.

Simply producing as per the demand in each week would result in a demand of 150 units being unfulfilled in Week 4. However, by prebuilding some units in the previous weeks, all the demand can be satisfied.

Thus, prebuilding 100 units in week 2 and 50 units in week 3 allows fulfillment of the full 250 unit demand in week 4, even though production was limited to 100 units in week 4.

Conclusion

Anyone running logistics processes with SAP will need to understand the different types of inventory SAP allows for. This blog post introduced you to the five key inventory types you will utilize in SAP IBP. From cycle stock to prebuild stock, you now have a better understanding of the options available to you.

Editor’s note: This post has been adapted from a section of the book Inventory Planning and Optimization with SAP IBP by Lei Wang, Sanchit Chandna, Jeroen Kusters, and Atul Bhandari.

Comments