Kitting is a VAS provided by a warehouse to deliver multiple products in a single fully packed form.

The kitting process performs the final packaging of multiple components, including product labeling or the dismantling/reassembling of already packed products. EWM supports the kitting of products based on customer orders, kit-to-stock processes, and reverse kitting.

We’ll explain these variations on the kitting process in SAP S/4HANA in the following sections.

Kit-to-Order Using a VAS Order

Based on customer requirements, you may be required to kit products or pack products and ship them to customers. In this case, all kit components might be produced or purchased to stock. When a customer order is created for a kit header, like assemble-to-order, the warehouse performs kitting activities and delivers the product to the customer. To support this kit-to-order scenario, the price should always be calculated at the kit header level, and all kit components should be consumed from the same warehouse.

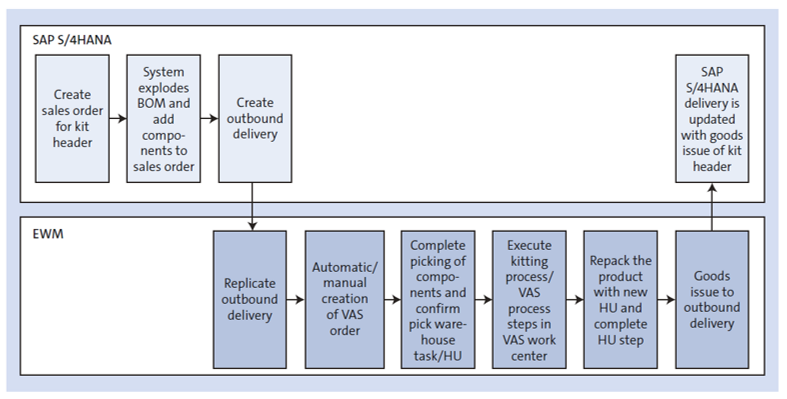

In the process flow shown below, a sales order is created for a kit header material.

The system explodes the BOM in a sales order and lists all the kit components required to deliver to the customer in a single packed form. An outbound delivery is created for the sales orders that ship the final product to customers. This outbound delivery contains both the kit header and kit components and is replicated in EWM. Based on existing VAS-related settings, a VAS order can be created automatically or manually. This VAS order determines the packaging specification from the kit header material and assigns the relevant VAS activities to perform. After the picking of the kit components from warehouse bins, VAS activities can be completed in a VAS work center. After completion of these VAS activities, repacking the product to an HU, and the complete HU step confirms the completion of the final packaging. A goods issue to an EWM outbound delivery posts the goods receipt for the kit header to stock and posts the goods issue to the customer delivery.

Kit-to-Order without a VAS Order

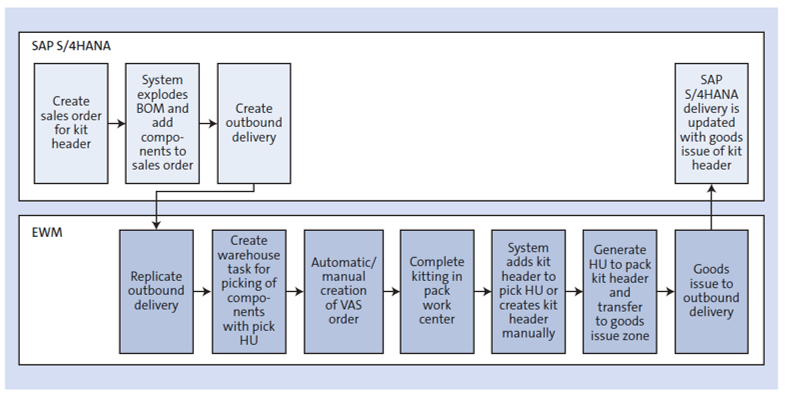

Kitting without a VAS order is performed through a packing work center, which also allows you to confirm generated kits. This process can be used when a packing work center is also used as a kitting work center. Kitting information can be tracked through an outbound delivery, and the long text maintained for warehouse requests.

In the process flow shown in the figure below, a sales order is created for a kit header, and kit components are exploded from a BOM. An outbound delivery for the sales order is created and replicated to EWM. In EWM, a warehouse task is created to pick the kit components with the pick HU for the outbound delivery created for the sales order. Kits components are available in the packing work center when the pick HU warehouse tasks are confirmed. Now, the system generates a kit header in the pick HU, or it can be generated manually in the pack work center. Executing the kitting process will pack the kit into an HU. Then, an HU warehouse task is generated to transfer the HU to the goods issue zone and confirm the warehouse task. When the goods issue is posted to the outbound delivery, kit stock is updated with movement type 512 and issued to the sales order delivery.

Kit-to-Order during Picking

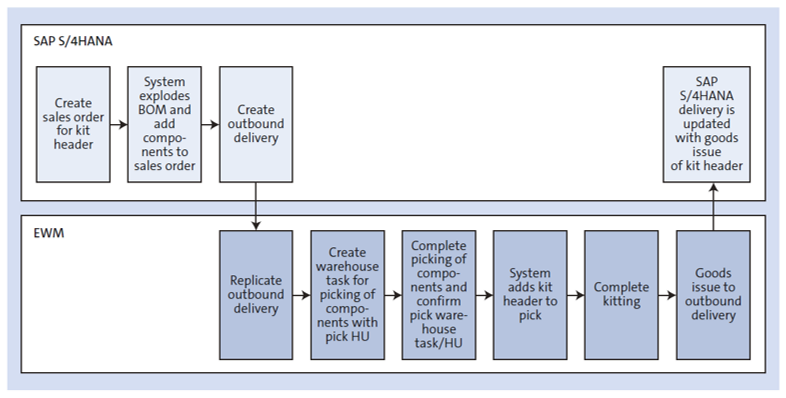

When kitting doesn’t require special activities or documented process, and thus can be performed without work centers, kitting during picking without VAS orders can be implemented. Kitting information is available in the outbound delivery for historical tracking. Kitting instructions can be added to a warehouse request’s long text.

In the process flow shown in below, a sales order has been created for the kit header, and kit components are exploded from the BOM. An outbound delivery is created for the sales order, and the outbound delivery is automatically replicated to EWM. In EWM, a warehouse task is created to pick the kit components with the pick HU from the outbound delivery created for the sales order. After kitting is completed, warehouse tasks with the pick HU are confirmed. Now, the system generates the kit header in the pick HU. When the goods issue is posted to the outbound delivery, the kit header receipt is posted and issued to the sales order delivery.

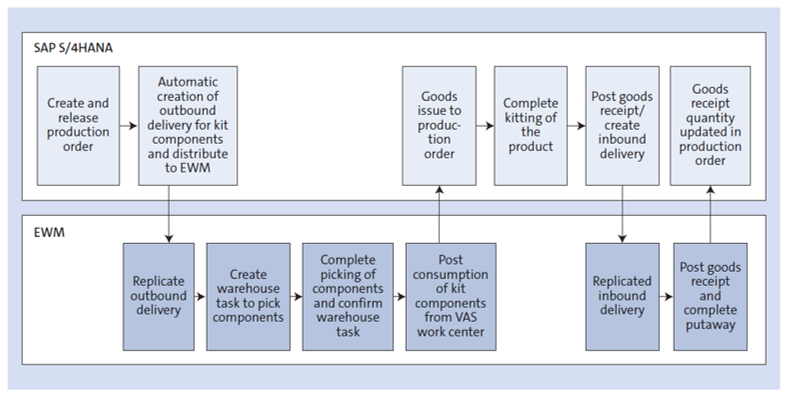

Kit-to-Stock with Production Orders

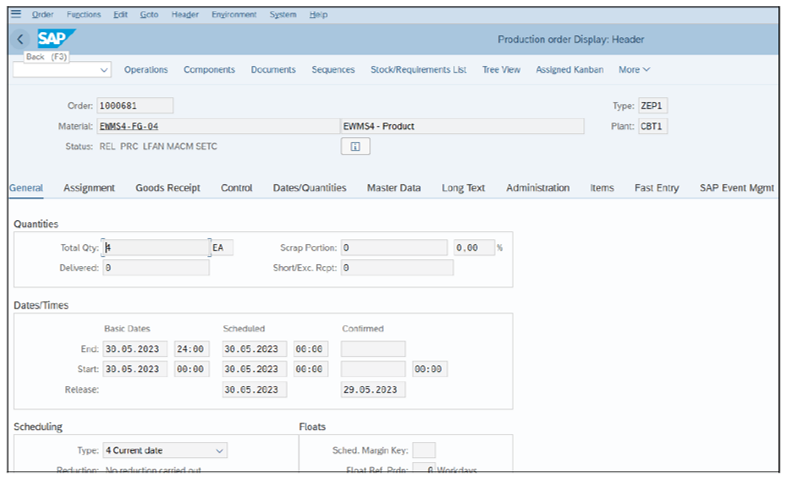

Production can initiate a kitting process through an SAP S/4HANA production order. When this production order is released, the system creates inbound and outbound deliveries and replicates them to the EWM system. The production order is updated with status LFAN (deliveries created), as shown here.

A VAS order is created automatically with relevant packaging specifications and the list of activities to be performed. After picking confirmation of components, process steps can be executed and confirmed at the VAS work center. In the process flow shown in the next figure, when a components consumption is posted in an EWM VAS order, a goods issue is updated in the SAP S/4HANA production order. When the goods receipt is posted to kit a VAS order, the inbound delivery is updated with the goods receipt. and the production order is updated with receipt. If quality inspection is required after kitting, a quality inspection lot is created at goods receipt.

Some limitations to kit-to-stock processes with production orders include the following:

- Orders with co-products and by-products

- Orders with network orders

- Rework orders created with trigger points

- Orders with non-stock items or subcontracting components

Internal Kitting

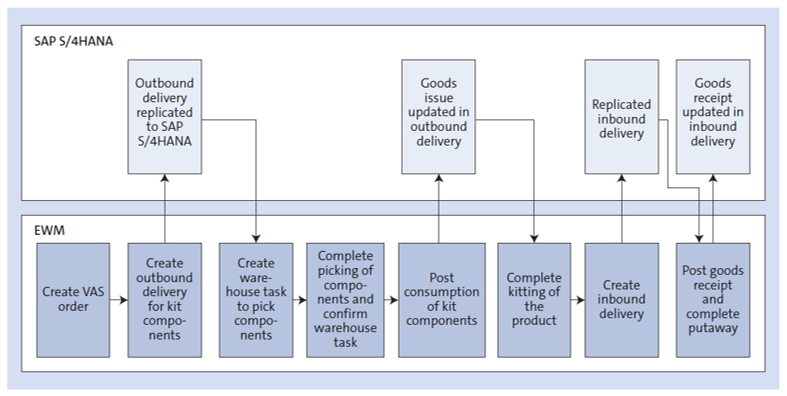

Like production orders, kitting also can be initiated directly in EWM through VAS orders. VAS orders can be created manually with Transaction /SCWM/VAS_KTS.

In the process flow shown below, a VAS order has been created in EWM, which generates an outbound delivery for picking and consuming kit components and an inbound delivery for the receipt of kit header material. The next step is to complete picking of the components and confirm the pick warehouse tasks created for outbound delivery. After components are available at the VAS work center for kitting, VAS activities are completed and the product is packed. The next step is to post consumption for kit components and receipt to kit. Components consumption at VAS order updates the outbound delivery with goods issue in EWM and replicates it to SAP S/4HANA. Also, the posting of the kit to the VAS order updates the inbound delivery with a goods receipt in EWM, which is replicated to SAP S/4HANA.

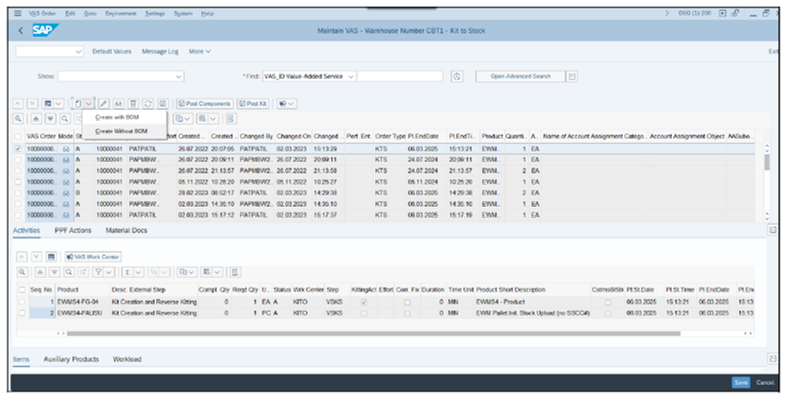

The figure below shows an example internal kitting order with automatic BOM explosion. The screen shows two options: Create with BOM and Create Without BOM.

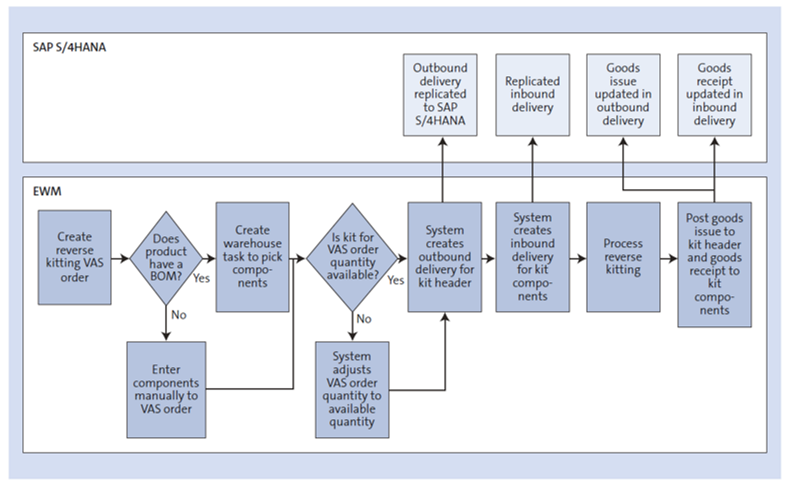

Reverse Kitting

Reverse kitting dismantles a kit into its components and then performs putaway to put the components back into stock. Components removed from the kit are available for another kitting order. During reverse kitting, a manual VAS order should be created with or without a BOM. A manual VAS order for reverse kitting can be created in Transaction /SCWM/VAS_KTR.

In the process flow shown in below, if a BOM exists, then the system automatically explodes the BOM and add components to the order. If the BOM doesn’t exist in the system, then you must manually add the components to dismantle. When a VAS order is created, the system creates an outbound delivery for consuming the kit header material and an inbound delivery to receive back the dismantled components to stock. After the reverse kitting activity is completed in the VAS work center, a goods issue and a goods receipt should be posted to account for the outbound and inbound deliveries.

Editor’s note: This post has been adapted from a section of the book Extended Warehouse Management with SAP S/4HANA: Certification Guide Application Associate Exam by Basawaraj Patil, Neetu Ramireddi, and Satish Komatlapalli. Basawaraj is a specialist leader at Deloitte with a focus on logistics execution. He has more than 20 years of SAP and supply chain experience in delivering complex supply chain and business transformation projects enabled by SAP S/4HANA. Neetu is a specialist master at Deloitte with more than 15 years of supply chain management experience and a focus on SAP Extended Warehouse Management and Logistics Execution. Satish is a specialist master in SAP manufacturing, quality management, and product lifecycle management. He has more than 19 years of consulting experience in delivering large-scale implementations and rollouts for global manufacturing customers.

Comments