The plant is, without doubt, the most important organizational unit for plant maintenance.

It fulfills several maintenance functions as both a maintenance planning plant and as a maintenance plant. We’ll look at both of these functions in the following sections, in addition to the topics of plant-specific maintenance and cross-plant maintenance.

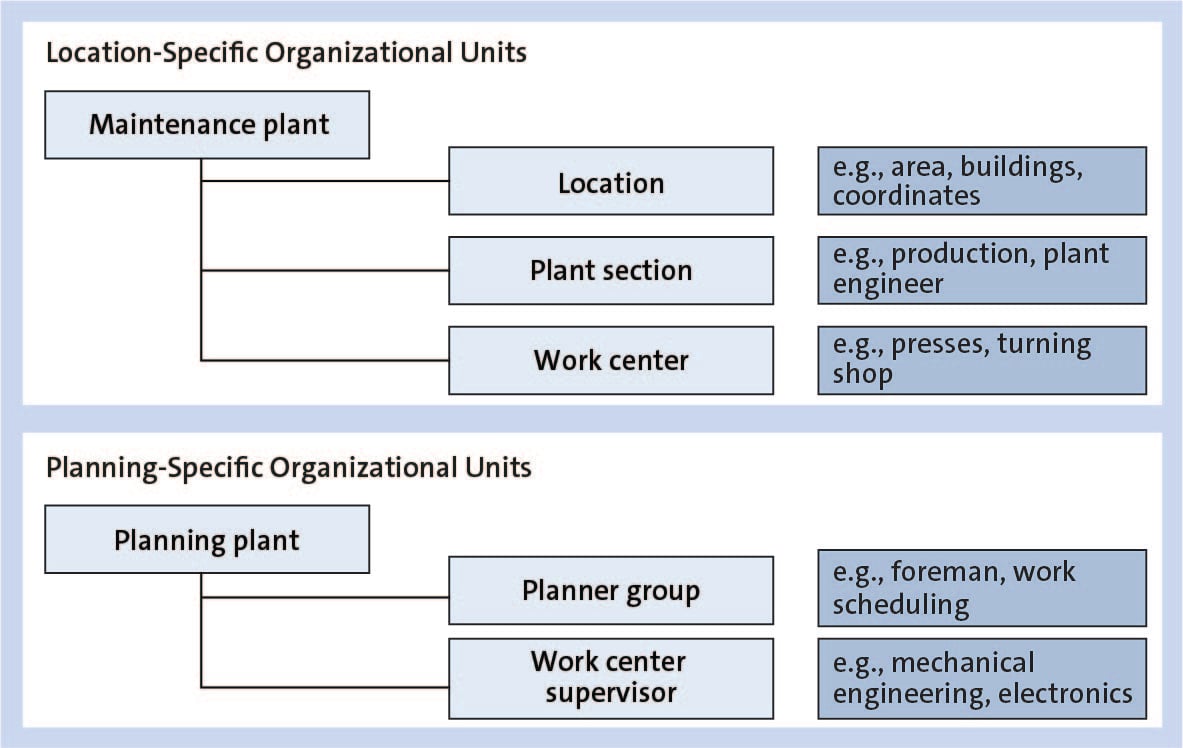

An overview of the various organizational units in SAP S/4HANA Asset Management is provided here:

Maintain Maintenance Planning Plant

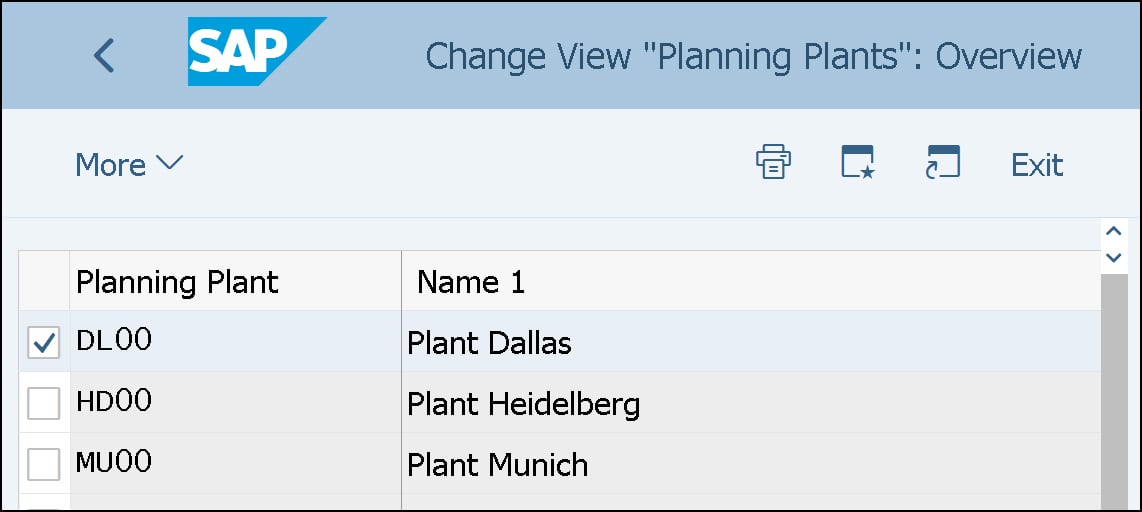

A plant is responsible for planning maintenance activities. This type of plant is called a maintenance planning plant (or planning plant for short). You use the Maintain Maintenance Planning Plant Customizing function to convert a plant to a planning plant.

Prerequisites

You must define the maintenance planning plant as a normal logistics plant beforehand.

Customizing Path

Enterprise Structure > Definition > Plant Maintenance > Maintain Maintenance Planning Plant

Settings

You obtain an overview of existing maintenance planning plants (see below), and you can add new plants to this overview.

Maintenance Plant: Assign Maintenance Planning Plant

All the technical objects to be maintained are physically present in a plant (functional location, equipment, and serial number). Here, this plant is known as a maintenance plant. A plant becomes a maintenance plant if you create a technical object there. Maintenance plants aren’t stored in a separate Customizing table.

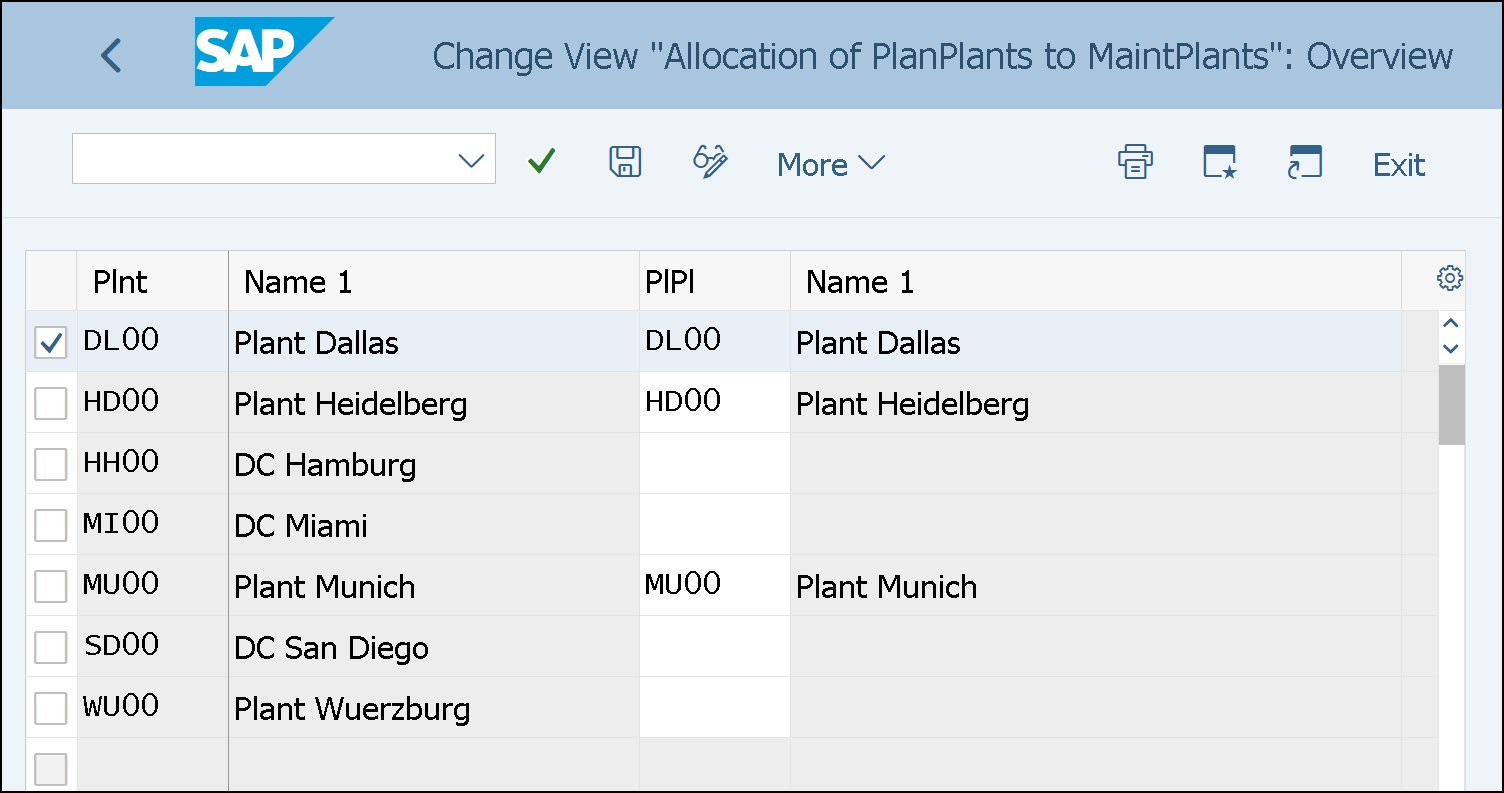

Every plant in which maintenance processes are to be planned or executed must have an assignment from the maintenance plant to the planning plant. You use the Assign Maintenance Planning Plant Customizing function to perform this assignment (shown in the previous figure).

Prerequisites

You must define both plants (maintenance plant and planning plant) as normal logistics plants beforehand. If a plant isn’t assigned to a planning plant (e.g., plant MI00), you can’t create any technical objects there (maintenance plant), nor can you plan or execute maintenance tasks (planning plant).

Customizing Path

Enterprise Structure > Assignment > Plant Maintenance > Assign Maintenance Planning Plant to Maintenance Plant

Settings

As shown in the next figure, in the PlPl column, assign the general logistics plant to a planning plant if it contains assets or if you want to plan or perform maintenance work.

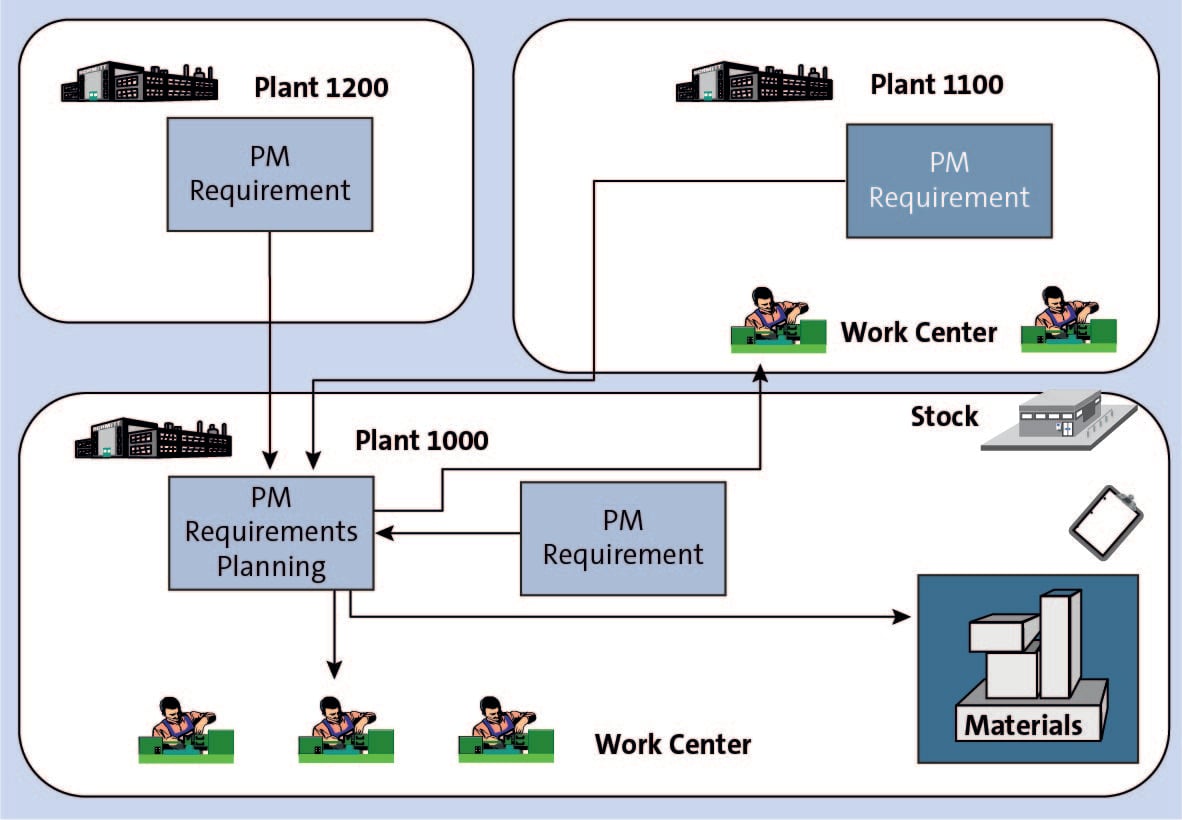

For business processes in SAP S/4HANA Asset Management, you need to differentiate between order planning and execution in only one plant and order planning and execution in different plants.

Plant-Specific Maintenance

In practice, you most frequently encounter a situation where the maintenance requirement is planned in the plant in which it originates, the orders are fulfilled by workshops in the same plant, and the spare parts are stored within the same plant. In the next figure, this plant is known as Plant 1000. Here, the following applies: maintenance plant = planning plant = spare parts storage plant.

Cross-Plant Maintenance

There are other options in addition to plant-specific maintenance:

- There is a requirement in a plant (here, 1200) because an asset is to be maintained there (i.e., in the maintenance plant), but all other functions (planning, order execution, and spare parts storage) are the responsibility of another plant (here, 1000).

- There is a requirement in a plant (here, 1100), and additional partial functions (order execution) are also the responsibility of this plant, but other partial functions (order planning and spare parts storage) are the responsibility of other plants (here, 1000).

Cross-plant maintenance isn’t a problem if the maintenance plant of the technical object and the plant of the executing work center are in the same company code. The same applies if the plants are in different company codes but belong to the same controlling area. This is also a standard scenario.

However, a problem occurs if the plants belong to different controlling areas. Here, there is no standard scenario but rather a customer-vendor relationship. Therefore, in this case, the maintenance plant (customer) has to trigger purchase orders, and the plant of the work center (vendor) triggers a sales order and its associated invoice. The invoice is, in turn, recorded as an incoming invoice in the maintenance plant. All in all, this is a very cumbersome procedure, but it can be simplified as described next.

Plants in Different Controlling Areas

If you implement cross-plant maintenance and your plants are in different controlling areas, the following approach is recommended:

- In the work center plant, create a cost center for the actual maintenance plant.

- Assign all the technical objects to the work center plant (as a maintenance plant) and to this cost center.

- Process all maintenance orders in the work center plant.

- Manually issue periodic invoices (e.g., monthly) from the work center plant whereby the customer maintenance plant is debited the amount, and the cost center is credited the same amount.

This procedure saves you from having to create purchase orders, sales orders, and individual invoices, as well as posting individual incoming invoices.

Editor’s note: This post has been adapted from a section of the book Configuring Plant Maintenance in SAP S/4HANA by Karl Liebstückel.

Comments