Inventory is the foundation of supply chain planning in SAP S/4HANA because every logistics and planning process depends on how stock quantities and values are classified, managed, and moved.

SAP S/4HANA uses stock types and special stock types to define the usability, ownership, valuation, and organizational level of inventory throughout procurement, production, and distribution. Understanding how these stock types represent different business processes—such as quality inspection, consignment, project stock, or stock in transit—is essential for planning material flows, controlling costs, and ensuring reliable supply chain execution.

Inventory defines the entire quantity of stock used in the business processes of an enterprise. Different product types result in different inventory types, such as raw materials, semifinished goods, work in process (WIP), finished goods, and spare parts. Inventory falls into different categories called stock types. In SAP S/4HANA, up to 60 different stock types can be defined in the system. Stock types define how inventory can be used in the business processes, on what organizational level they are maintained, and how the inventory is valuated. In addition to the inventory stock types, there are a few stock types not controlled by inventory management.

In SAP S/4HANA, stock types are represented technically by the Stock Type field and the (optional) Special Stock Type field, plus additional keys. The key combinations defining the inventory stock types used in your SAP S/4HANA system can help you understand your inventory management processes. Frequently used inventory stock types in SAP S/4HANA business processes are as follows:

- Unrestricted-used stock: Stock can be consumed in any business process.

- Blocked stock: Stock is blocked from any usage, except transfer postings.

- Quality inspection stock: Stock is subjected to quality inspection. This stock type might be managed by quality management in SAP S/4HANA.

- Transfer stock: Stock is moved from one organizational unit to another in a two-step process only by means of inventory management.

- Stock in transit: Stock is moved from one location to another but isn’t available for consumption. There are different subtypes of stock in transit depending on the kind of transfer of goods and title. These processes stretch beyond inventory management and involve internal procurement and logistics execution.

- Vendor consignment stock: Stock is owned by the vendor but is available for consumption in your business process.

- Customer consignment stock: Stock is owned by you as a supplier but located at a customer site and ready for consumption by the customer.

- Orders-at-hand stock: Stock is linked to a specific sales order item.

- Project stock: Stock is linked to a specific project.

Some stock types are closely linked to industries processes, such as tight empties (retail) or stock provided to the (subcontracting) vendor. Thus, the stock type might exist only at the plant level (customer consignment stock), whereas other stock exists on the storage location level.

Noninventory stock types in SAP S/4HANA include the following:

- Reservations

- Nonvaluated goods receipt blocked stock

In a nutshell, stock types and special stock types define the process ownership of a stock quantity and the corresponding stock value. Transitioning from one stock type to another is key to defining the business process in logistics. For example, say you procure semifinished goods via vendor consignment (special stock type K) into the quality inspection stock (stock type), because you set up the respective quality management-specific data in the material master (i.e., inspection type).

After a successful quality inspection, you provide the unrestricted use stock (stock type) to your subcontractor as a component (special stock type O with key vendor ID) while taking over its ownership. Eventually you receive the finished goods from your subcontractor as unrestricted use stock (stock type) while posting the consumption of the stock provided to the vendor (special stock type O with key vendor ID).

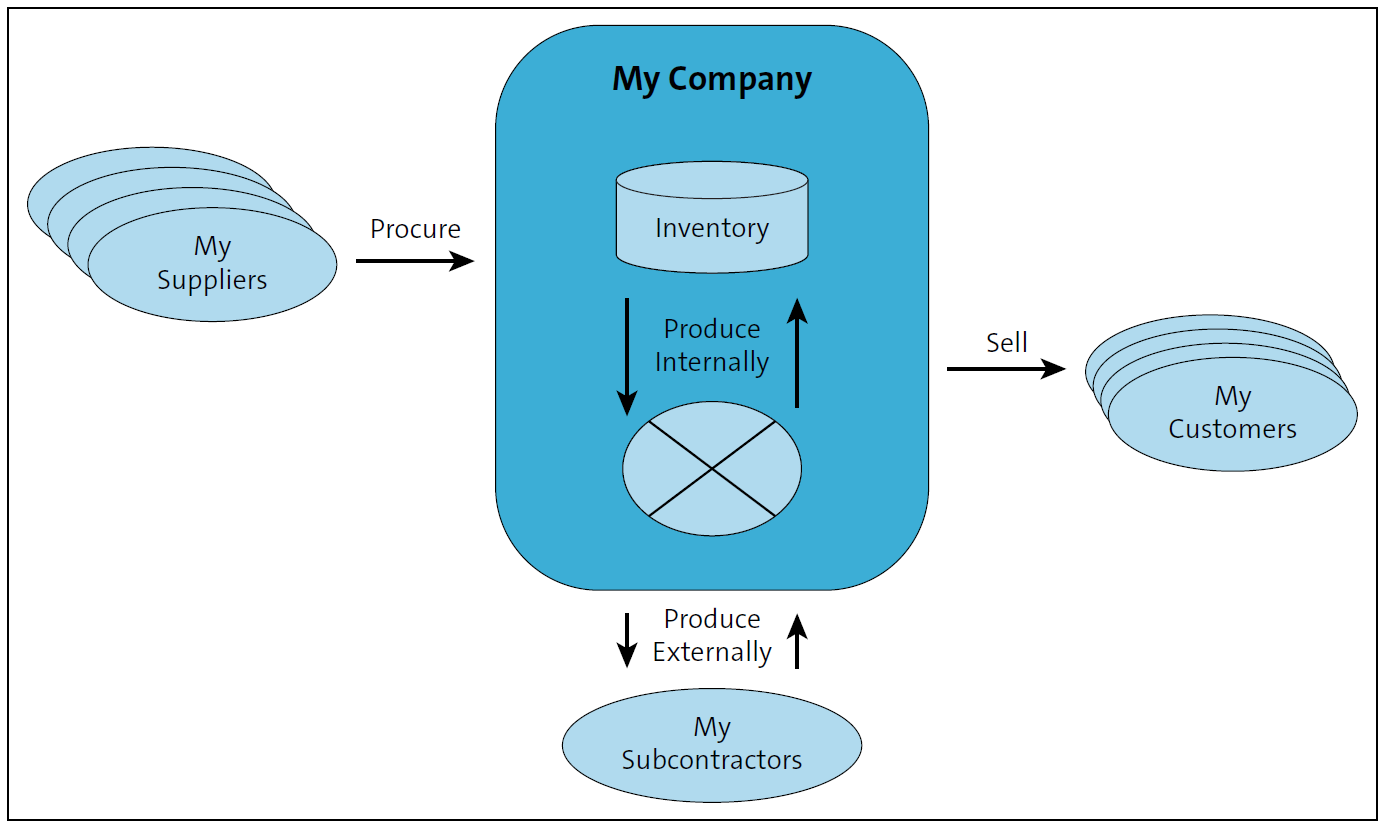

The flow of inventory within an enterprise is called the supply chain. Thus, inventory is the key factor to be looked at in supply chain planning. Inventory can be created by external procurement and/or internal production.

This figure shows the principal components of a supply chain for an example company called My Company.

Inventory is either procured externally, produced internally, or produced by subcontractors externally. Inventory is consumed within production processes and eventually sold as a finished product. These principal components might be combined differently depending on the involved products, product lifecycle, location strategy, or market requirements.

An optimal supply chain keeps the costs linked to inventory low (procurement, production, warehousing, distribution) while providing the desired service level to all customers. Depending on your business process, there are multiple strategies to achieve this goal:

- Just in time (JIT)/just in sequence (JIS) production: Prominently used in the automotive industry to ensure that all components of a car reach their final assembly step exactly at the moment they need to be consumed.

- Kanban: Helps to simplify your inventory replenishment strategy by using predefined lot sizes tied to moving containers. Learn more about Kanban in SAP S/4HANA here.

- Demand-driven material requirements planning (DDMRP): Material requirements planning (MRP) strategy that aims to to decouple bottleneck steps in supply chain planning.

- Vendor-managed inventory: Shifts the inventory management responsibility to the vendor of a component.

- Make to order (MTO)/make to stock (MTS): Allows you to plan your inventory based on concrete demands or on demand forecasts.

- Make or buy: Decision regarding whether or not you outsource the procurement of a component/ finished good to an external contractor.

Conclusion

In SAP S/4HANA, inventory serves as the central link between procurement, production, and sales within the supply chain. Stock types and special stock types define not only where inventory resides, but also how it can be used, who owns it, and how it is valued at each step of the logistics process. By clearly structuring inventory flows and applying appropriate planning strategies—such as JIT, Kanban, DDMRP, or make-to-stock—organizations can balance service levels with cost efficiency and build a resilient, well-planned supply chain.

Editor’s note: This post has been adapted from a section of the book Inventory Management with SAP S/4HANA by Bernd Roedel and Johannes Esser. Bernd is chief development architect within a central architecture team in the area of supply chain management (SCM) core logistics, where he has supported SAP S/4HANA development for the last ten years. Johannes joined SAP in 2002 and is a development manager in SAP development and a certified Scrum master.

This post was originally published 1/2026.

Comments