The most common type of sales order-driven individual requirement is what companies in the United States refer to as “drop shipments.” In this blog post, we’ll provide an overview of the drop shipment process with SAP S/4HANA.

Drop Shipping Process Overview

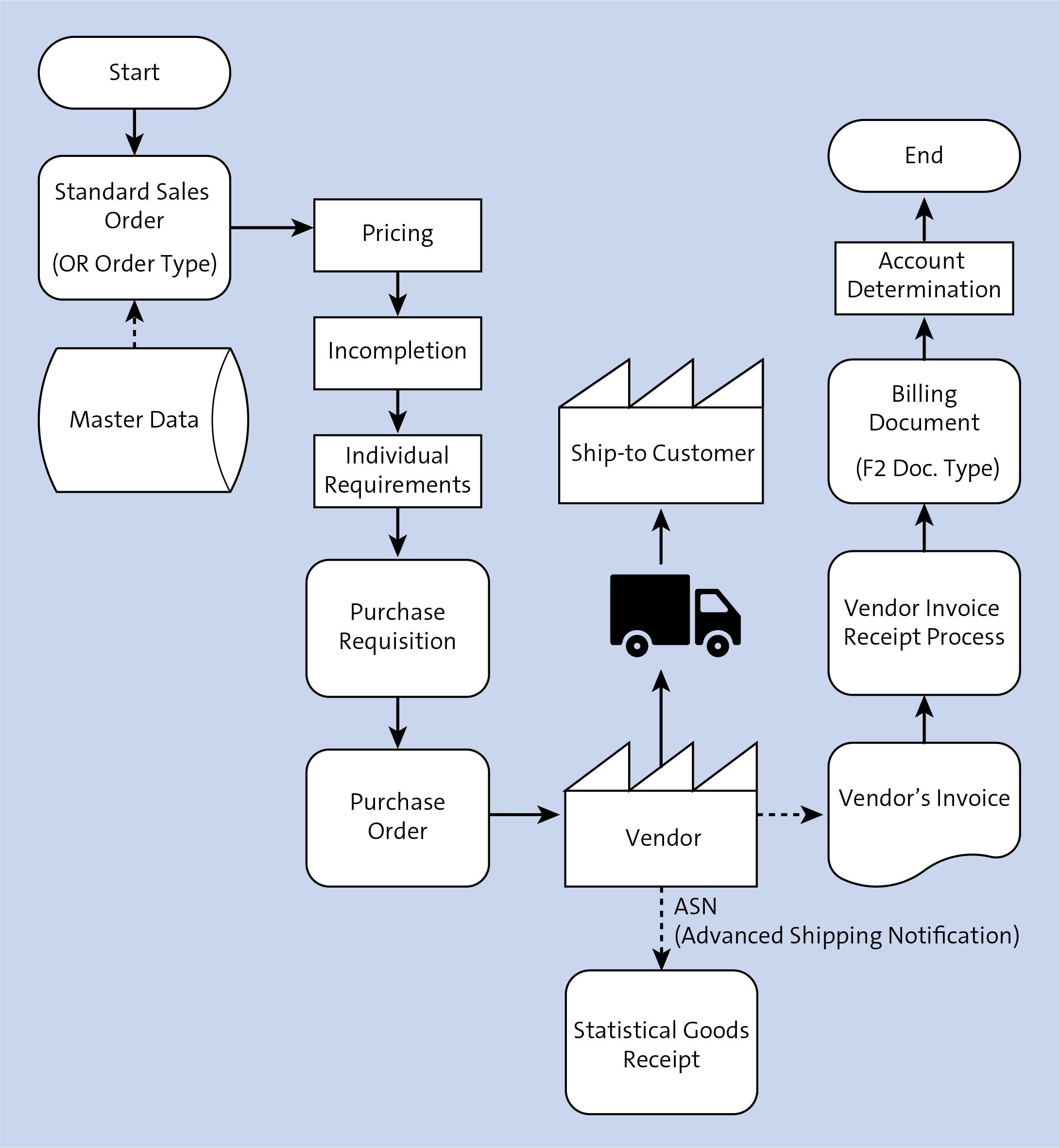

Drop shipment is the language used in day-to-day operations to refer to the process shown in the figure below.

To enable this process, the first step is to set the material master data field, Item Category Group, in the Sales view.

The first option is to use item category group CBNA when the vendor doesn’t provide you with an advanced shipping notification (ASN). In other words, you’ll wait for the vendor invoice before is using your own invoice to the customer.

The second alternative is using item category group CBOR (third-party sales order with shipping notification). In this case, you expect the vendor to provide the ASN, and then you’ll issue your own invoice to the customer based on the quantities specified in the ASN. Item category CBOR is often preferred because your invoice to the customer is issued sooner than with CBNA. CBOR is also more compatible with other delivery-based customer scenarios such as standard orders; that is, you issue the invoice immediately upon shipping the order.

The decision to use item category group CBNA or CBOR depends on how reliable you consider your vendor to be in notifying you of shipments. When you receive goods receipt notification electronically, for instance, via Electronic Data Interchange (EDI) message 856, using item category group CBOR is common, but if you rely on manual email notifications, you may consider using item category group CBNA. You can rely on the vendor to send you invoice because otherwise they won't get paid.

After you enter a sales order, for example, using standard order type OR, the item category assigned to the line containing the CBNA material will be defined as CB2. This line will only be complete after the purchase requisition is created and its number assigned to the order. This process happens automatically when you save the order; it's controlled by the schedule line category incompletion procedure.

Item category CB2 will lead to the determination of the schedule line category CT (third-party without shipping notification), which is configured with a purchase document type. After the sales order is saved, the purchase requisition number can be viewed on the Schedule Line tab of the line details. In the purchase requisition document, the delivery address will match the ship-to address.

The purchasing team will take the purchase requisition and convert into a purchase order. This process is usually performed by a background job that can be scheduled. Once created, the purchase order is sent to the vendor either electronically (EDI message 850) or via email, fax, print/mail, etc. When the vendor receives your purchase order, they will create a sales order in their system using your customer ship-to address as their ship-to address. From the vendor's perspective, that is a delivery address that they may decide to track as master data in their system; however, tracking isn't necessary because the delivery address on your purchase order to them is usually treated as a one-time customer delivery address (as you would with your customers).

After the vendor fulfills your order, they will send you an ASN message either electronically or via email, phone call, fax, print/mail, and so on. You’ll record the ASN by performing an operation called the statistical goods receipt (Transaction MIGO), which is a materials management (MM) operation that indicates that the order was received but inventory won’t be created.

The vendor will then send you their invoice, which would go through the regular invoice receipt process (Transaction MIRO) that MM uses for other vendor invoices. The vendor receives payment via accounts payable.

After the vendor invoice is received, a sales order containing the CB2 line will become relevant for billing, which is usually processed by a background job. The invoice is created, sent to your customer, and payment is collected by accounts receivable. This process is now concluded.

The statistical goods receipt could make the CB2 sales order line relevant for billing right away, but because item category group CBNA was used, it's configured to wait for the vendor invoice to be received before you issue your invoice to the customer. This scenario is controlled by the Billing Relevance flag on the item category configuration. The CB2 item category is configured with the Billing Relevance F (Order-Related Billing Doc. - Status According to Invoice Qty), which makes the system wait for the vendor invoice to be received.

If you use item category group CBOR in the material master, the item category CB1 and schedule line category WS are defaulted. The configuration for item category CB1 has Billing Relevance G (Order-Related Billing of the Delivery Quantity), which is what causes your invoice to be issued after the statistical goods receipt.

Most companies in the United States use CBOR/CB1/WS (with Billing Relevance G), a common business practice to issue an invoice at the time of shipping. However, you must be mindful that after you perform this change, if you don't perform the statistical goods receipt, this invoice won't be issued even if the vendor sends you an invoice.

Note that the item category groups CBNA and CBOR affect the default item category CB2/CT and CBS/WS, but you're allowed to manually change the item category, thus allowing you to process exceptions if they come to pass. For instance, if a material is set as CBOR, but the vendor didn't send you the ASN and sent the invoice, you could change the item category in the sales order from CB1 to CB2 to allow the invoice to be issued even without the statistical goods receipt.

Schedule Line Category

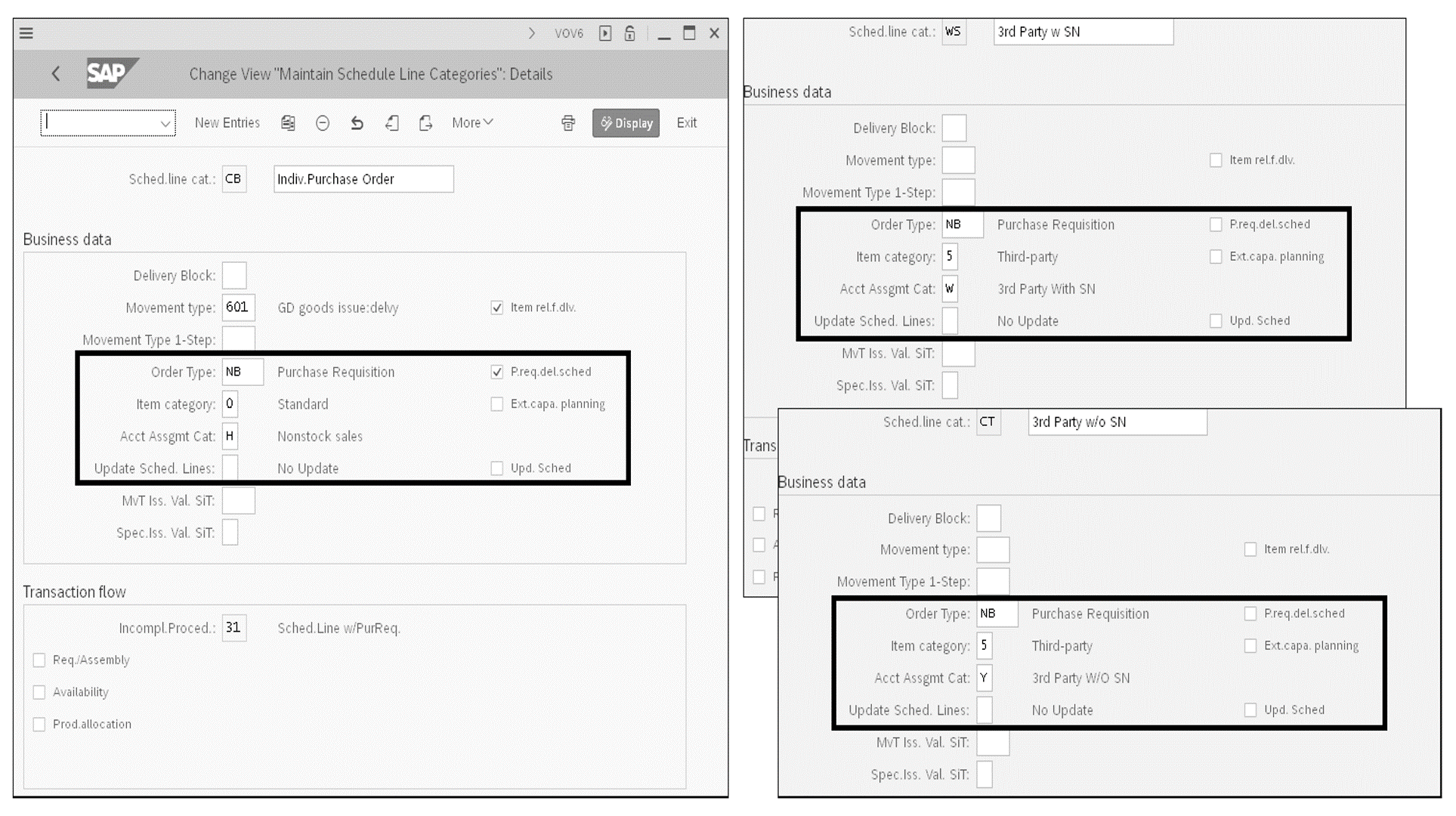

To configure sales document scheduling line categories, open Transaction VOV6 or follow the menu path SAP Customizing Implementation Guide > Sales and Distribution > Sales > Sales Documents > Schedule Lines > Define Schedule Line Categories. On the screen that opens, select the item category CB, CT, or WS and then click the Details button or press (F2).

As shown in the figure below, the purchase Order Type is used for a third-party ordering solution (drop shipment). You must create a purchasing document (typically a purchase requisition) along with the sales order upon saving, and this Order Type will be used. The SAP standard value is NB, but your materials management team may request that you change the document type for a custom one (e.g., ZNB).

The Item Category field is a type of purchasing document line that must be created for third-party ordering scenarios (drop shipment).

The P.req.del.sched (purchase requisition delivery schedule) flag is used in special order, third-party ordering scenarios (for instance, when you want to receive goods from the supplier into your facility first before shipping to the customer). In this scenario, you’ll schedule the delivery to the customer along with the receipt from the vendor. Thus, you must select this flag.

When checked, the Ext.capa.planning (external capacity planning) flag indicates that you're using SAP Supply Chain Management (SAP SCM) to estimate the capacity of the vendor in fulfilling this order. This enhances the accuracy of the expected delivery date, which in turn will improve the accuracy of your promise date to your customer. It requires a lot of setup to be implemented, as well as ongoing maintenance.

The Acct Assgmt Cat (account assignment category) field allows you to indicate that the purchasing document created by this schedule line will require an additional costing element (such as a cost center).

The Update Sched. Lines field is used in third-party ordering scenarios to control if/how you want to update the sales order schedule line with purchase order delivery information. Suppliers may provide you with an ASN before you receive product. You may want to reflect this scenario on the schedule line or wait until product is fully received at your warehouse. The Update Sched. Lines (from the purchase order) flag controls whether you want to update schedule lines at all.

Conclusion

Drop shipping is a common way to fulfill sales orders. In this blog post, we explored the drop shipping process with SAP S/4HANA Sales, and how to schedule line categories.

Want to learn about SAP S/4HANA logistics? Read here.

Learn SD with SAP S/4HANA in Our Rheinwerk Course!

Dig into SD! Understand the organizational structure and master data in SAP S/4HANA. Learn to customize basic and cross-functional settings in SAP S/4HANA, and then focus on SD processes and their configuration: ATP, pricing, sales processing, shipping, and billing. Take a close look at SD simplifications and enhancements to get the most out of your system! Get access to course recordings by clicking the banner below.

Editor’s note: This post has been adapted from a section of the book Configuring Sales in SAP S/4HANA by Christian van Helfteren.

Comments