The material master record is the central source for material-specific data. It is used in all areas of logistics. In this blog post, we will concentrate on the structure of the material master data, the maintenance of material master records, and some important fields.

Structure of the Material Master Data

To avoid redundancy, material data is stored in a single database object. A material should only be created once in the system and is assigned a unique number.

All areas, such as purchasing, inventory management, MRP, work scheduling, warehouse, and so forth, all access the stored data together. Since many departments use the material master, the material master contains a lot of data. A specific user department is not interested in all the information stored in the material master, but usually only in the data related to its business activity. For this reason, material master data is structured in so-called views that correspond to the user departments: in the material master, you will find purchasing-specific, sales-specific, warehouse-specific data, and so forth.

A material automatically receives a maintenance status, depending on the views maintained. If you want to use a material for a process, the system checks whether the material has the required maintenance status—that is, whether the required views have been maintained.

Depending on the purposes for which you want to use a material, you must have maintained certain views:

- When purchasing stock material, the Purchasing and Accounting views must be maintained (at minimum).

- If you also want to plan this material, you must have maintained the MRP view.

- For the purchasing process of a non-stock material for which you want to create a material master record, you only need the Purchasing view.

In parallel to being structured according to views, the material master is set up along the organizational structure. What does that mean in concrete terms? A material master record contains data that is valid for the whole company: the material number, the material description, the assigned material group, the base unit of measure, the weight, and so on. This data is maintained at the client level in the material master.

A material master also contains data that is plant-specific. In MRP, for example, you can define the planning procedure or lot-sizing procedure for each plant. In the area of purchasing, you can, for example, define per plant whether automatic purchase requisitions are allowed or not (using an indicator in the material master). You also decide for each plant (the plant is the valuation level) how a material is to be valuated and at what price. A lot of data relevant for purchasing, MRP, or stock valuation is therefore maintained at the plant level.

Another level where specific material master data can be maintained is the plant storage location level. At this level, you can, for example, maintain a storage bin with the informative character only.

Note: The previously mentioned organizational levels (client, plant, and storage location) are the ones relevant for the external procurement process and inventory management. Other organizational levels can be relevant for other activities. For example, you would maintain sales data depending on the sales organization and distribution channel, and you would specify a warehouse number and storage type for warehouse management data.

Maintaining Material Master Records

The breakdown of material data according to user departments and organizational levels is also reflected in material master record maintenance. When you maintain material master records, you must go through several dialog screens before you start creating, changing, or displaying data.

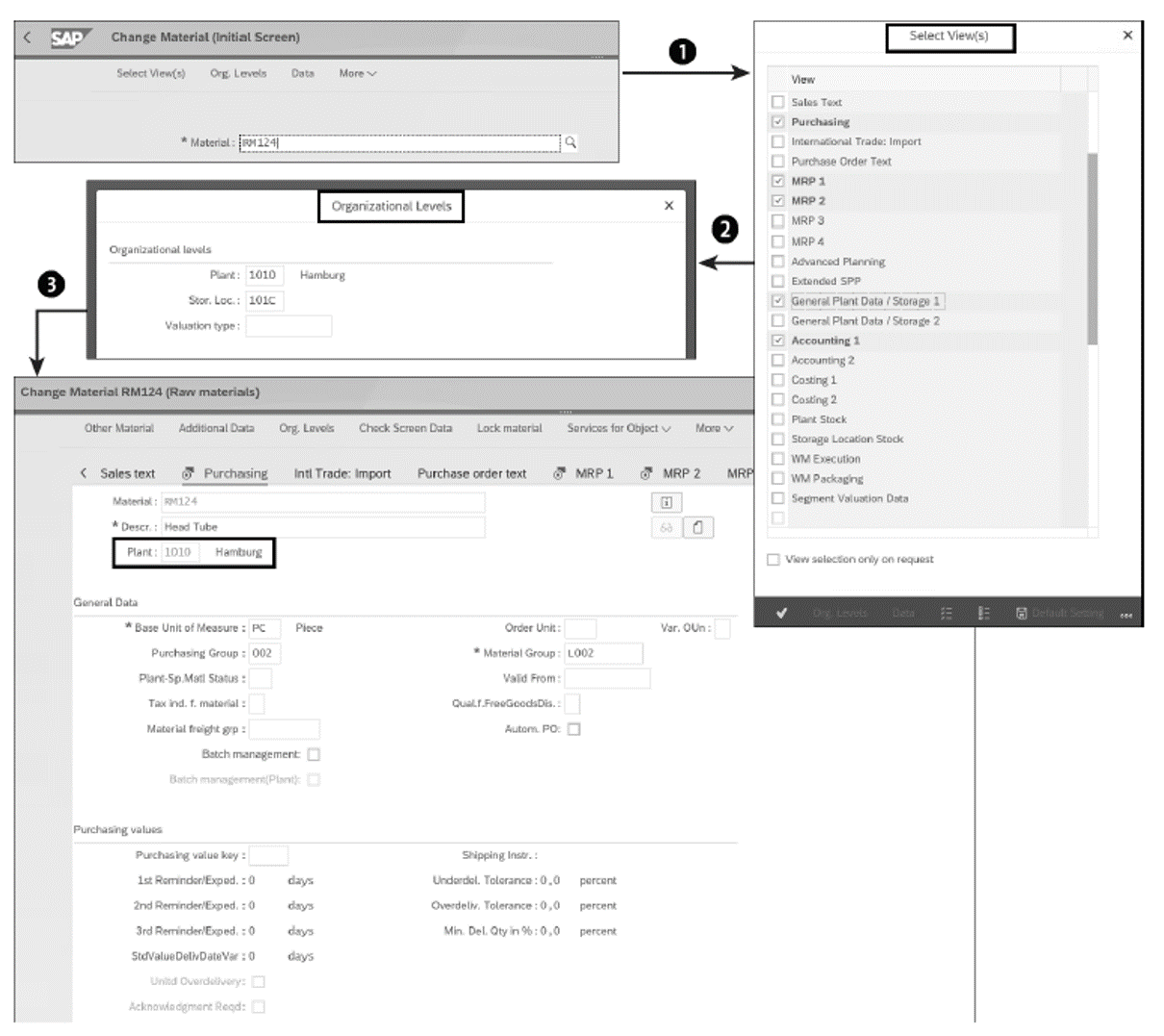

The below figure illustrates this: After the initial screen, you see two consecutive dialog boxes. In the Select View(s) dialog box (1), you specify the views you want to process. In the Organizational Levels dialog box (2), you enter the relevant organizational levels. Next, you see the data screens (3). The data of the material is organized according to views and organizational structure. Here you can see the purchasing data for plant 1010.

You can preset both the organizational units and the views to be selected and save this setting. If you have made and saved a default selection, you can even run the dialog boxes in the background.

Example Between Material Change and Material Extension

The following examples illustrate the difference between material change and material extension:

Example 1

You have already created the Purchasing view of a material for a certain plant, but now you discover that the purchasing group you have stored is no longer correct and you want to store a different purchasing group. To do this, you must choose the Change Material app. You are changing the contents of an existing view/organizational unit.

Example 2

You have already created the Purchasing view and the Accounting view of a material for a certain plant, but now you want to extend the material by the MRP view. To do this, you must choose the Create Material app. You are creating a new view.

Example 3

You have already created the Purchasing view of a material for a certain plant, but now you want to create the Purchasing view for a second plant. To do this, you must choose the Create Material app. You are creating data for a new plant.

Important Material Master Fields

In this section, we will describe some important fields that are generally relevant.

Material Type

Each time you create a new material master record, you must select a material type to which the material is to be assigned. Materials with the same properties are assigned to the same material type. Examples of material types are raw materials, semi-finished products, and finished products.

The material type is a key, each material is assigned to a material type, and the material type performs important control functions. Among other things, the material type influences the following:

- Which number the material should have (internally assigned, user assigned, numeric, alphanumeric, number range, and so on)

- Whether the material should be a product or a service

- Which screens appear in which sequence during material master maintenance

- Which fields in the master record are required fields, optional fields, or hidden fields that should only be displayed (in other words, the material type influences field selection control)

- Which procurement type is allowed for the material (produced in-house, procured externally, or both)

- Which valuation classes can be specified in the material master record—that is, which accounts are posted to for goods movements of this material

- Which views can be created

- For which plants are quantity and value-based inventory management allowed, only quantity-based inventory management allowed, or no inventory management allowed at all

In standard SAP S/4HANA, various material types are available for use. If you need additional material types, you can define them in Customizing according to your requirements.

Industry Sector

Like the material type, the industry sector is a key, can be created and maintained in Customizing, and has a control function. When you create a material master record, you must specify an industry sector. The industry sector determines the following.

- Which screens are displayed and in what sequence

- Which industry-specific fields are displayed on each screen

The industry sector that you assigned when you created a material master record cannot be changed later. But in Customizing, you can define new industry sectors to modify the screen and field selection according to your requirements.

The industry sector is usually unique to a company. Once it has been defined, it can be preset so that a user does not have to make the same entry each time.

Material Status

The material status is a field that you can assign in the material master record if you want to restrict the usability of a material. It is a key that is configured in Customizing. Depending on the Customizing settings, a material status can prevent a material from being purchased (e.g., in case of a phase-out material) and/or moved in the warehouse (e.g., because of quality issues) and so on. Alternatively, a warning can be issued. This restriction can be planned with a valid-from date.

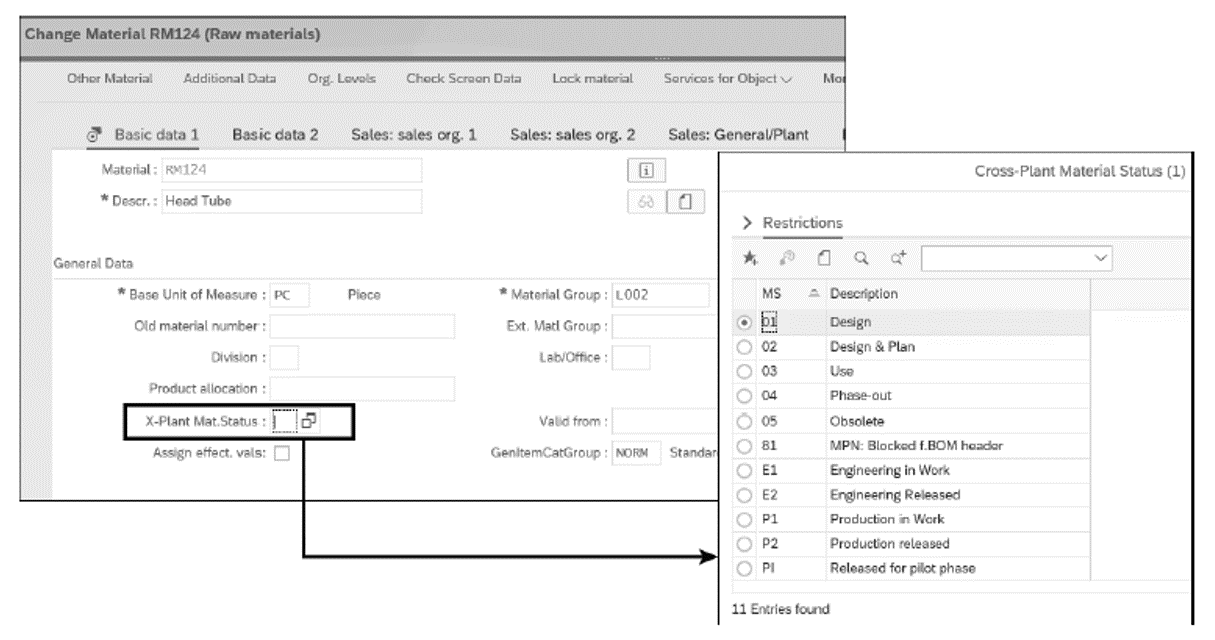

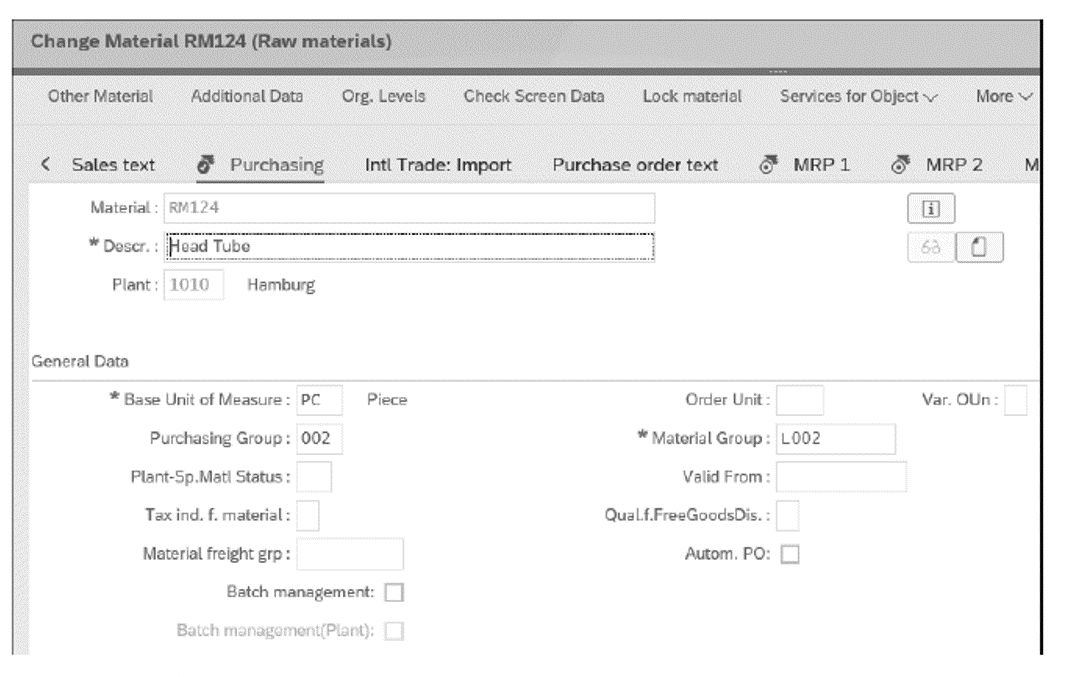

You can set either a cross-plant material status or plant-specific material statuses. The first figure shows possible entries for the cross-plant material status and the second shows the plant-specific material status with the valid-from date on the Purchasing view.

Note: The plant-specific material status can be entered not only in the Purchasing view but also in other plant-specific views

Conclusion

Anyone utilizing SAP to perform logistics operations should be acquainted with the material master. In this post, we introduced you to the concept and gave you some important information on fields to know when getting started.

Learn more about SAP S/4HANA logistics here.

See why the material master is important in SAP S/4HANA here.

Editor’s note: This post has been adapted from a section of the book SAP S/4HANA Sourcing and Procurement Certification Guide: Application Associate Exam by Fabienne Bourdelle.

Comments