The most important master data in SAP S/4HANA, at least from the logistic point of view, is the material master.

It represents a product that can be purchased, produced, stocked, sold, or costed, and many other business transactions can be posted with reference to a material.

As the name suggests, MRP is centered on the material master. Requirements such as a forecast or a sales order are created with reference to a material, and the MRP run will generate replenishment proposals for this material in order to cover the shortages.

The following are the most important material types in SAP from an MRP perspective:

- Finished products: These are usually products manufactured by the company and sold to customers. The standard material type for a finished product is FERT.

- Semifinished products: These products are also manufactured internally, but they are generally not sold; they are used as components for finished or other semifinished products. The standard material type HALB identifies semifinished products.

- Raw materials: These are materials that a company purchases from a supplier and uses to produce semifinished or finished products. The standard material type for raw materials is ROH.

Other standard material types can also be considered by MRP. It is even possible to create a custom material type for a specific process. But these three types are the most commonly used in manufacturing processes.

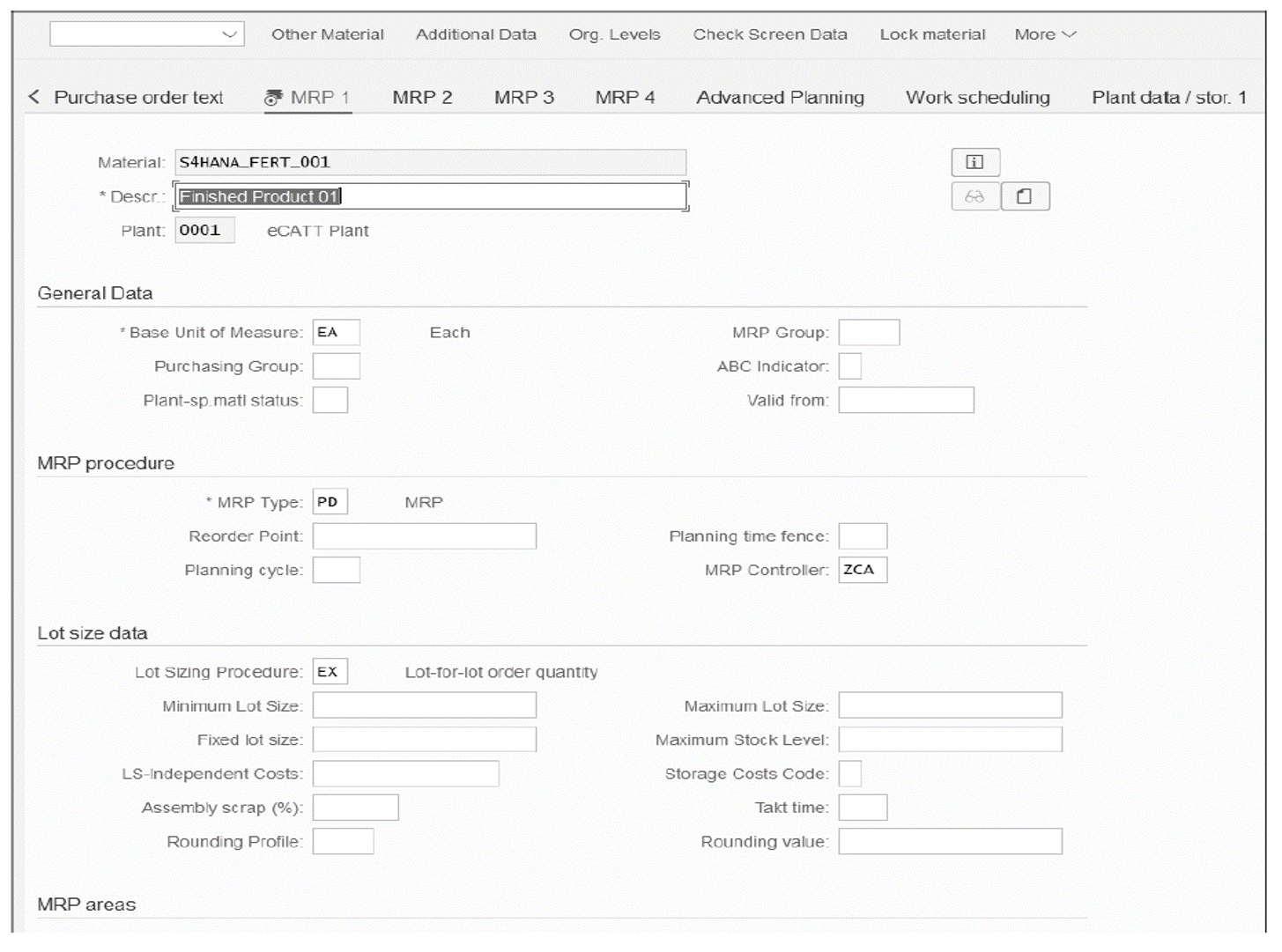

The material master is created in Transaction MM01, and there are four tabs in the material master to store the MRP-relevant settings. The figure below shows the details of the MRP 1 tab in the material master. In addition to general data, this is where we will find information about the MRP procedure, lot sizes, and MRP areas in the corresponding sections of the screen.

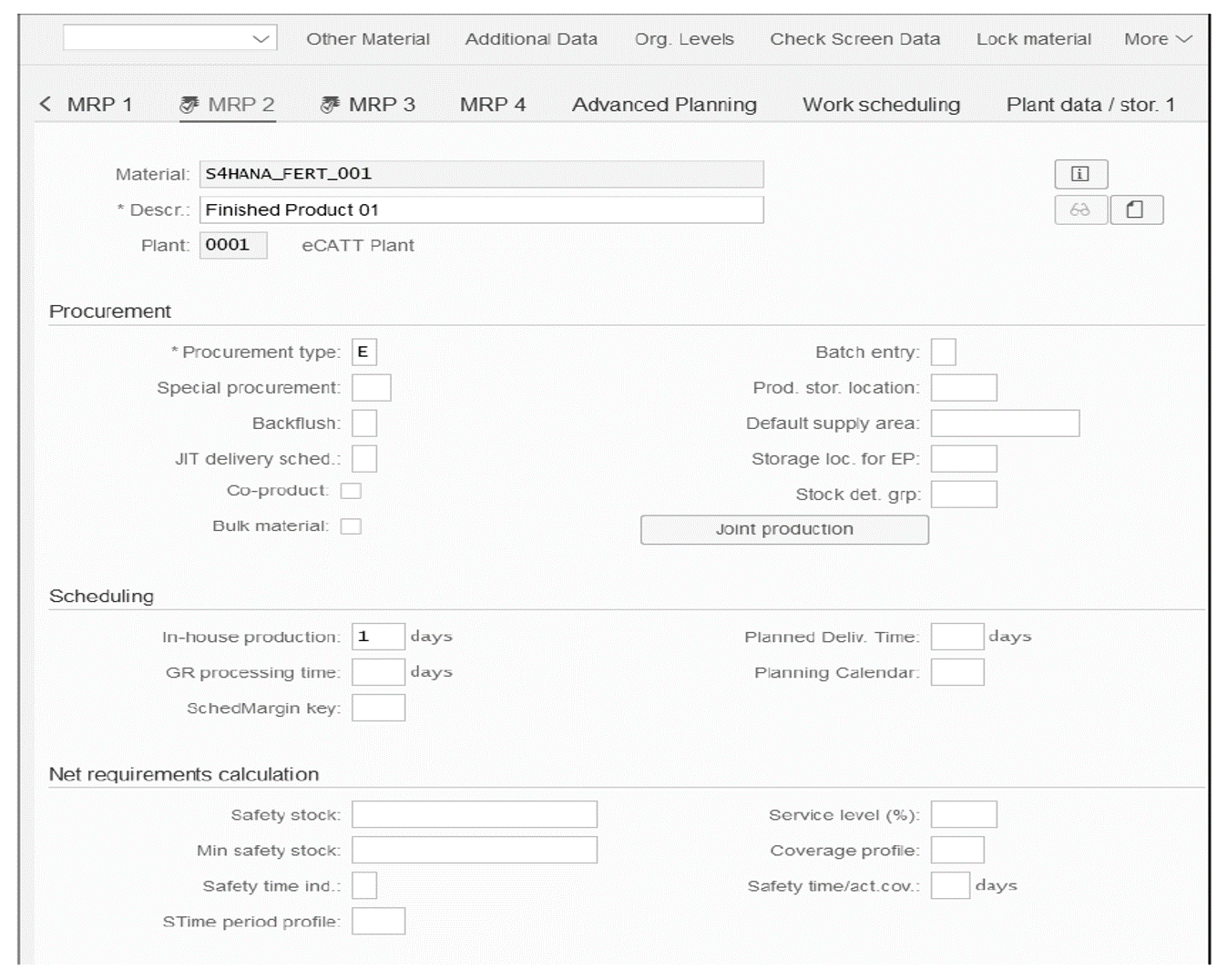

The MRP 2 tab shown below displays details about procurement, scheduling, and net requirements calculation in the corresponding sections:

- In the Procurement section, we can indicate if a material will be produced internally or purchased, for example, or which storage location should be used by MRP for this product.

- In the Scheduling section, we can record the default values for internal and external procurement, including how much time a material takes to be produced internally or procured externally and how much time it takes to receive it in the warehouse.

- The most important fields of the Net Requirements Calculation section are the Safety Stock field (which is used to add a stock buffer in the MRP calculation) and the Coverage Profile

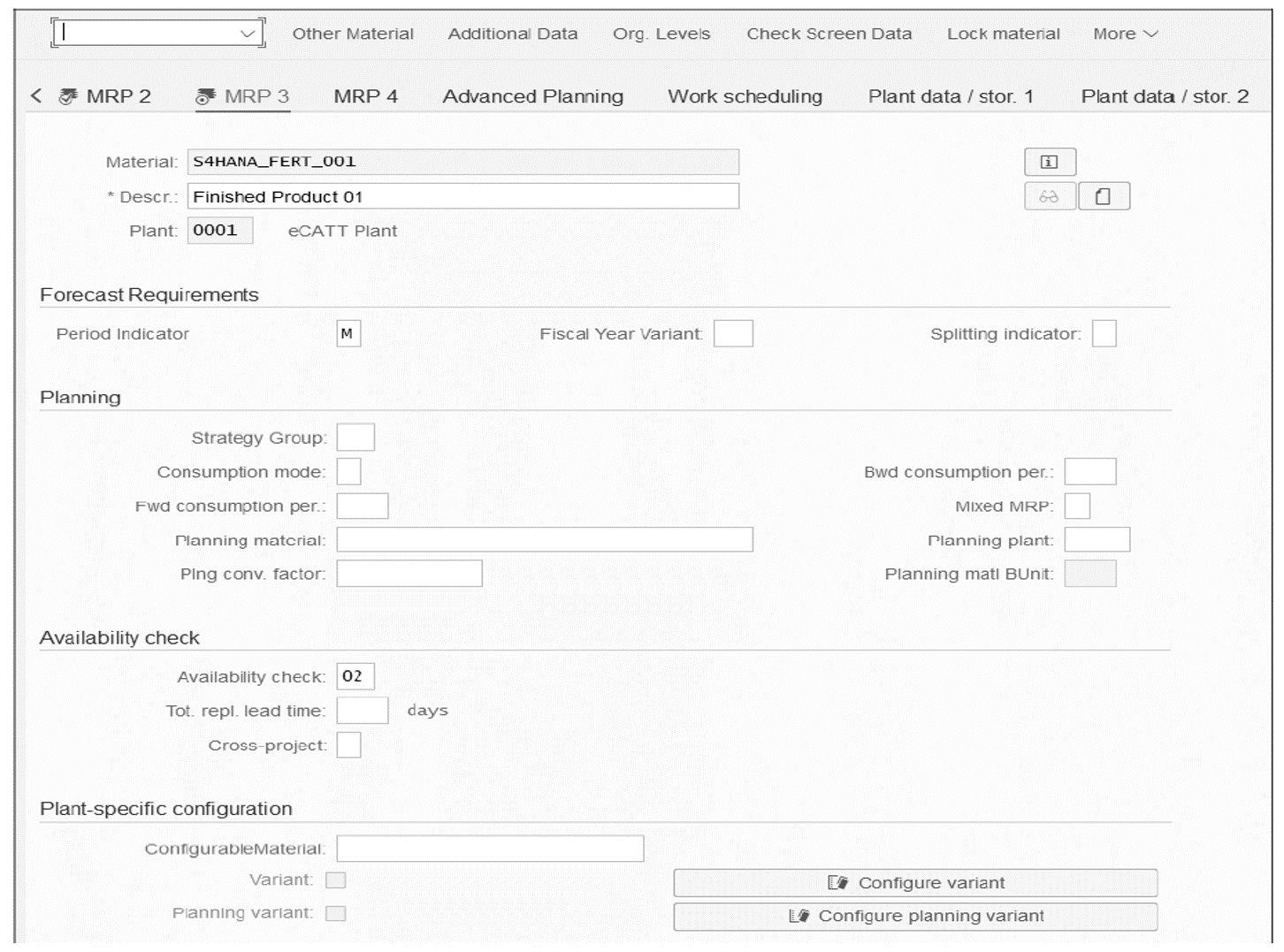

The Planning section is the most important section of the MRP 3 tab in the material master, as shown in the next figure. This section contains settings related to demand management. Another important section of this tab is Availability Check, which stores settings related to the ATP check that are used not only by MRP but also in many different areas across the system.

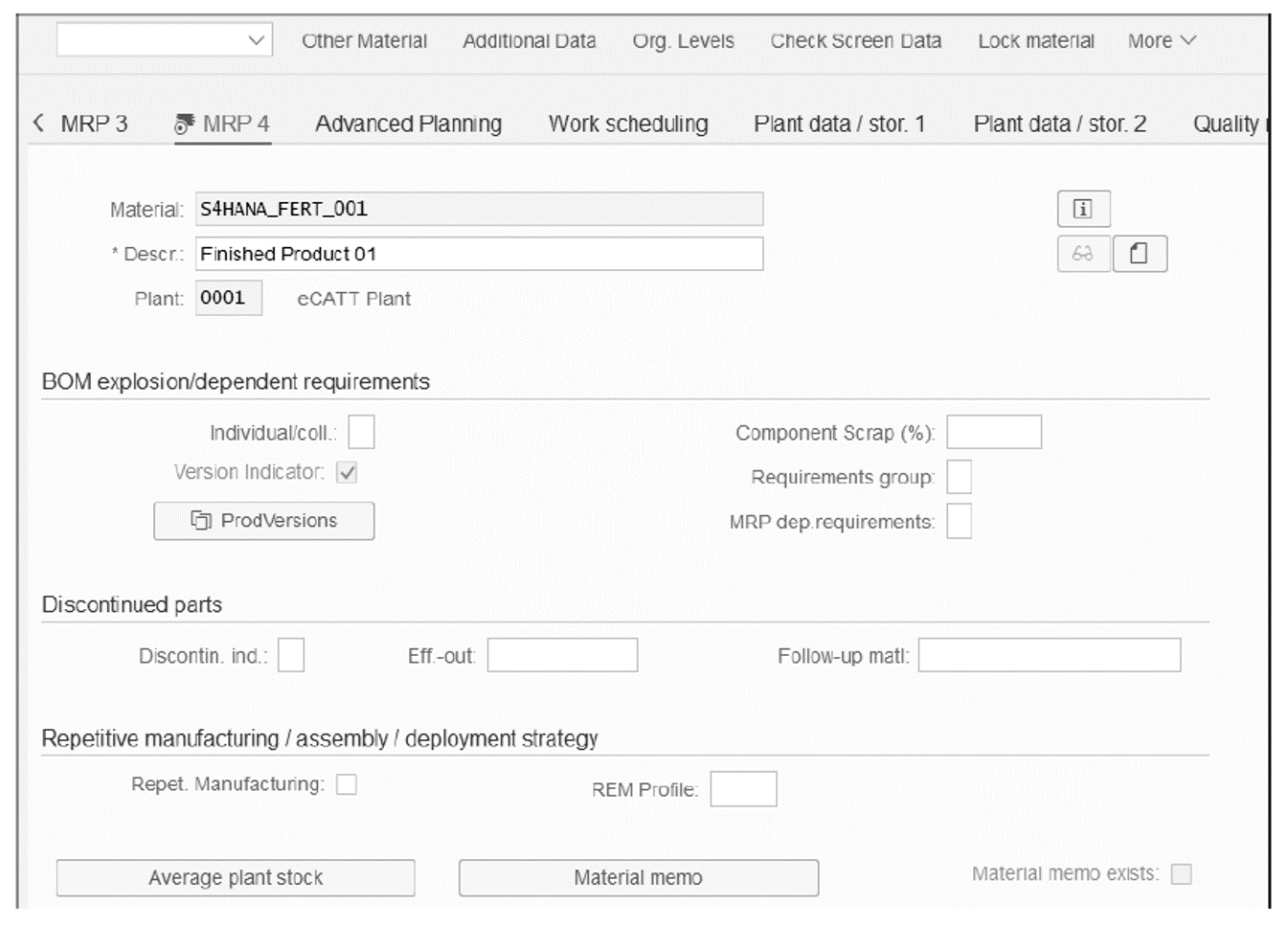

Finally, the MRP 4 tab shown in the next figure displays information related to BOM explosion/dependent requirements, discontinued parts, and repetitive manufacturing.

Note: If we compare the material master MRP tabs of an SAP S/4HANA system with the MRP tabs of an SAP ERP system, we will see that several fields are missing from SAP S/4HANA, especially in the MRP 4 tab. This is basically because SAP tried to reduce the effort of material master maintenance in SAP S/4HANA, removing fields that were no longer relevant due to simplifications. SAP Note 2267246 provides more information about these simplifications implemented in the material master.

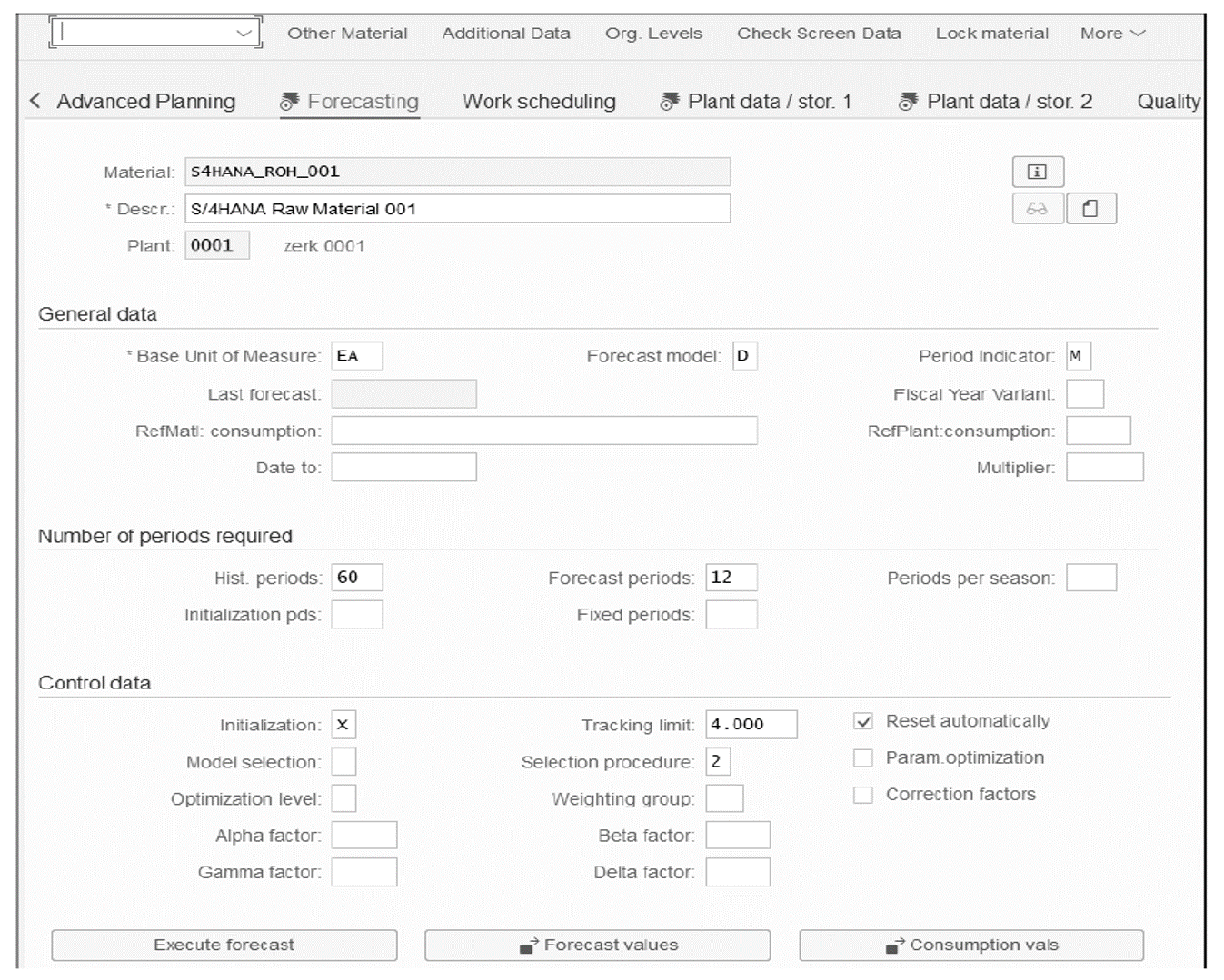

In addition to the four MRP tabs, the Forecasting tab in the material master is also relevant for MRP. This tab generally should be extended to the material master when using a forecast-based MRP type.

3

The figure below shows the Forecasting tab and all the fields relevant to the forecast. Here we define, for example, the forecast model to be used to when the forecast is executed, the number of historical periods to be analyzed, the number of forecast periods, and additional information related to the forecast. In this tab, we can also manually include or change the forecast values and the consumption values or manually execute the forecast by clicking the respective buttons.

Warning: According to SAP Note 2268100, material forecast transactions, such as Transaction MP30, can still be used in SAP S/4HANA, but are not considered a future technology.

Finally, the Work Scheduling tab in the material master is relevant for materials produced internally only, and it contains fields mostly related to production and process order execution. However, some of those fields are also relevant for MRP, such as the Lot Size Dependent In-House Production Time field or the Production Scheduler Supervisor field.

The Manage Product Master Data app is also organized in tabs, but to access the MRP data, you first need to select the plant, and then all the MRP related settings can be found under the MRP Data tab

Learn more about the material master in this post.

Editor’s note: This post has been adapted from a section of the book Material Requirements Planning with SAP S/4HANA by Caetano Almeida.

Comments