Production planning assists organizations in managing and strategizing their manufacturing and production procedures.

The module in SAP is structured to facilitate the entire production cycle, encompassing planning, scheduling, MRP, production execution, and monitoring.

Production planning enables organizations to create production plans and schedules based on customer demand, sales forecasts, and available resources. It also allows them to track and manage inventory levels, production costs, and quality control processes. Some key features of production planning include the following.

Capacity Planning

This feature allows organizations to plan and manage their production capacity to ensure that they can meet customer demand without overburdening their resources.

Bill of Materials (BOM) Management

Production planning enables users to manage BOMs for their products, which includes the list of materials required for production, as well as the quantities and the order in which they need to be used.

MRP

Production planning uses MRP to help organizations determine what materials are required for production and when materials need to be ordered or produced.

Production Scheduling

This feature allows users to schedule production based on available resources and customer demand.

Integrating production with a warehouse management system (WMS) can enhance the efficiency, accuracy, and productivity of both production and warehouse processes. Real-time tracking of raw materials, components, and finished products can prevent stock shortages or overstocking. Planning and scheduling production runs becomes easier, ensuring on-time delivery of products. Automating manual processes decreases errors and improves data accuracy, leading to better decision-making and lower costs. Additionally, reduced lead times and increased responsiveness to customer demands are other benefits that can be realized. Overall, integrating production with a WMS improves supply chain visibility and operational efficiency, resulting in increased customer satisfaction and profitability.

By combining the production planning, materials management, and SAP EWM modules, efficient production management can be achieved. This is possible due to the modules providing end-to-end visibility and control over the entire production process. The production planning module facilitates production planning and scheduling, while the SAP EWM module covers goods receipt and goods issue process.

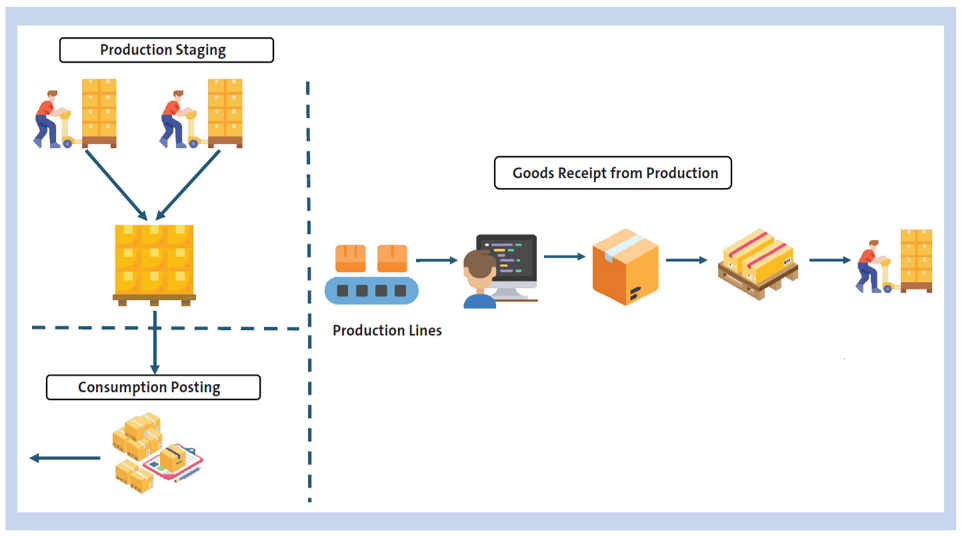

By integrating production processes with SAP EWM, the precision of inventory management has been enhanced, enabling improved tracking of raw materials, components, and finished goods. Furthermore, it facilitates real-time monitoring of production activities, leading to informed decision-making based on up-to-date data. Moreover, the integration of production processes with SAP EWM offers enhanced inventory visibility by allowing the receipt of final products directly from production to warehouses. It also enhances the operation of production supply areas by optimizing the staging of components and semi-finished materials. Finally, posting the goods consumption provides improved inventory and cost visibility.

The process of integrating production processes with SAP EWM commenced in the early 2010s with the introduction of production integration functionality. This enabled real-time communication between SAP EWM and other SAP modules, including production planning and materials management. The result was a more cohesive and integrated approach to warehouse and production management.

SAP EWM has undergone significant evolution over the years, continuously enhancing and adding new capabilities to better cater to the dynamic needs of businesses in warehouse and production management. Presently, SAP EWM is widely adopted across various industries, and its integration with production processes remains a vital aspect of the solution.

The primary objective of integrating production and extended warehouse management, as shown in the figure below, is to facilitate the timely and efficient staging of products, also known as production staging, from the warehouse to the assembly line. This step also involves posting consumption for the production process, returning unused components, and receiving finished products into the warehouse.

Modern automated warehouses employ a variety of technologies, including material flow systems, automated storage and retrieval systems, automated guided vehicles (AGVs), and warehouse robotics solutions, to fulfill production integration requirements. By leveraging these technologies, businesses can optimize warehouse operations, lower costs, and enhance productivity, resulting in improved business outcomes.

The integration of SAP EWM with production processes in SAP S/4HANA is gaining popularity in several industries, including discrete manufacturing, process manufacturing, and repetitive manufacturing. This integration serves various business functions, such as transferring raw materials or semi-finished components from the warehouse to production lines and receiving finished or semi-finished materials from production or assembly lines to the warehouse.

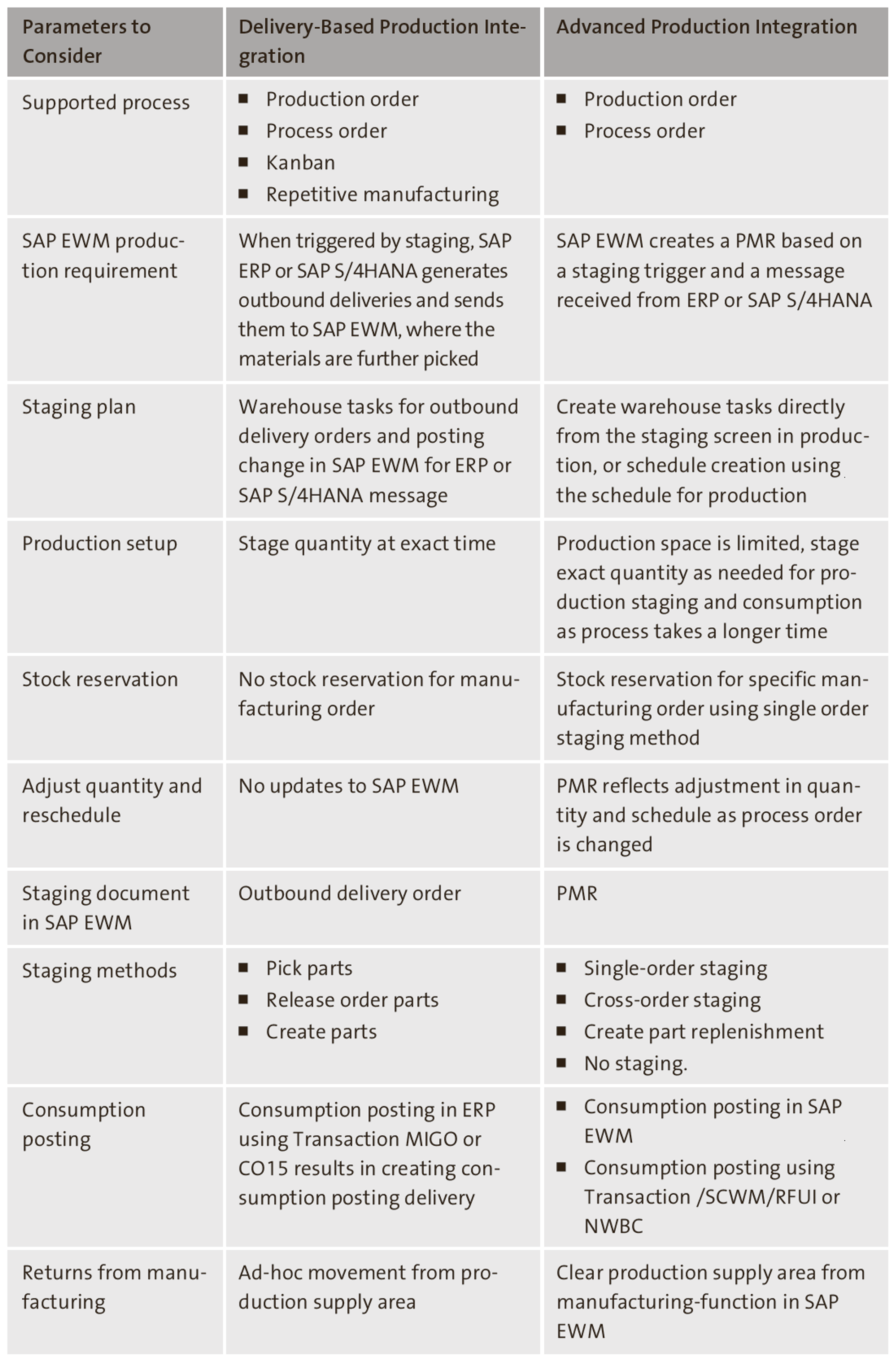

To cater to the industry-specific and business-specific process needs for producing finished goods, SAP EWM offers two production integration options that can be customized according to your requirements.

Delivery Based Production Integration

Since the launch of SAP EWM 7.0, SAP has provided delivery-based production integration capabilities. This feature enables the ERP system to generate delivery documents for both the materials that require staging and those that need to be consumed. Subsequently, SAP EWM receives these delivery documents for material picking and consumption posting. In essence, this methodology relies on delivery documents.

Advanced Production Integration

Beginning from SAP EWM 9.2, advanced production integration option has been provided by SAP for production processes. Through this option, a production material request (PMR) is created in SAP EWM when the ERP system sends a message with the requisite information. This integration is essentially founded on the concept PMR.

The table below displays a comparison between delivery-based production integrations and advanced production integrations.

Some key concepts in production planning include the following:

Production Supply Area

A production supply area is a physical location adjacent to the production lines where raw materials and semi-finished goods are staged. This area is typically located in close proximity to production lines. Within SAP EWM, a production supply area is regarded as master data.

Control Cycle

A control cycle establishes the connection between the demand source, such as a production line, and the supply source, which could be an external supplier or warehouse.

Editor’s note: This post has been adapted from a section of the book Integrating EWM in SAP S/4HANA by Shailesh Patil and Sudhakar Bandaru. Shailesh stands as an eminent solution architect and subject matter expert at Infosys Limited, showcasing a remarkable and extensive career spanning 19 years of expertise in supply chain management solutions. Sudhakar is a highly accomplished digital logistics execution solution architect with extensive experience in various modules, including SAP EWM, SAP Yard Logistics, and SAP Transportation Management, spanning an impressive career of over 19 years.

Comments