If the scheduling function is switched off in SAP S/4HANA, then delivery and transportation dates are calculated equally as all activities can be performed on the same date.

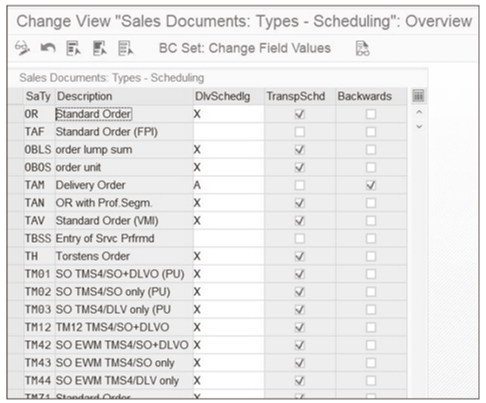

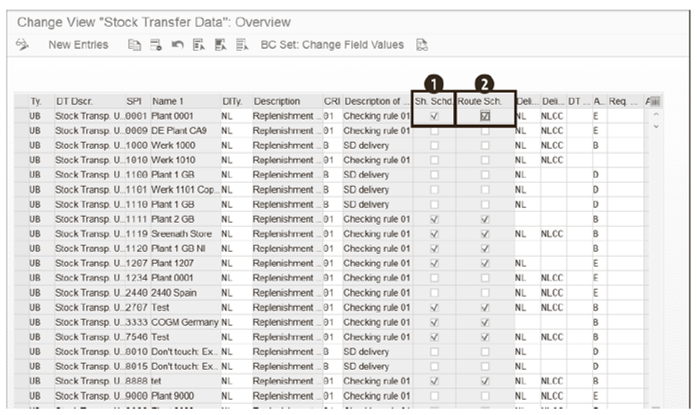

Delivery and transportation scheduling is activated on the level of order types in sales and distribution. For stock transport orders, the activation is done on the level of order type and plant. In this blog post, we’ll cover the setup of scheduling for different documents using SAP S/4HANA.

Scheduling Menu Paths

For sales documents, scheduling is activated in Customizing via path SAP IMG > Sales and Distribution > Basic Functions > Delivery Scheduling and Transportation Scheduling > Define Scheduling by Sales Document Type.

For stock transport documents, scheduling is activated under Customizing node SAP IMG > Cross-Application Components > Advanced Available-to-Promise > Configure Activities for Specific Document Type > Stock Transport Orders.

(1) Shipment scheduling

(2) Route scheduling

Transportation Scheduling Lead Times

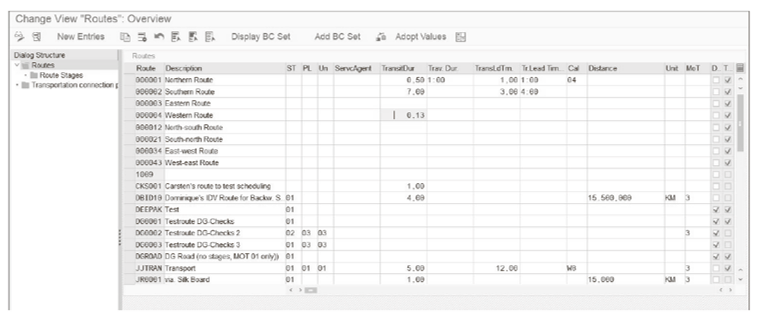

The transit time and unloading time define the lead time for transportation scheduling. When an ATP check is triggered, the system does backward scheduling from the requested delivery date (LFDAT). The transit time is used to arrive at the goods issue date (WADAT). The transit durations are normally derived from the route. Using the shipping functions, you can set up a region-based route determination. Once a route has been determined for a requirement, the transit duration from the route is used as the lead time for scheduling. In addition to the transit time, the route also specifies the transportation lead time, which is used to determine the transportation planning date.

Delivery Scheduling Lead Times

The picking/packing time and the loading times define the lead times for delivery scheduling. These lead times are based on the shipping point. When an ATP check is triggered, the system does backward scheduling using the transit times to arrive at a goods issue date (WADAT). From the goods issue date, backward scheduling using the loading time is used to arrive at the loading date (LDDAT). The picking/packing time is used to arrive at the requested material availability date (MBDAT). If the requested material availability date lies in the past or the ATP check can only confirm later than the requested material availability date, a forward scheduling is triggered to calculate the confirmed scheduled dates.

The lead times for delivery scheduling are defined in the route or the shipping point. The setup is done in Customizing via SAP IMG > Logistics Execution > Shipping > Scheduling > Delivery Scheduling and Transportation Scheduling.

In this section, you’ll learn how to set up durations for activities.

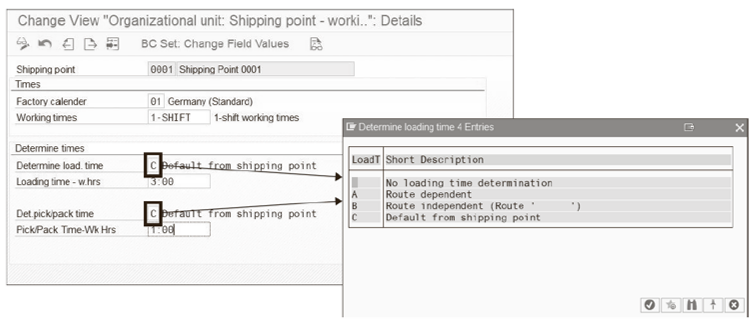

Define Scheduling by Shipping Point

The lead time information for scheduling is maintained in the shipping point This includes the factory calendar, working hours (shifts), and delivery lead times. The picking/packing and loading times can be configured to be picked up from the shipping point or determined via the route.

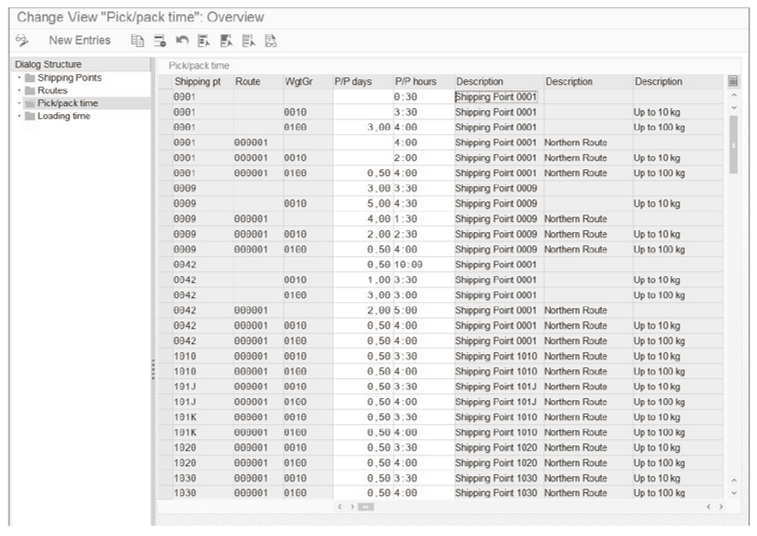

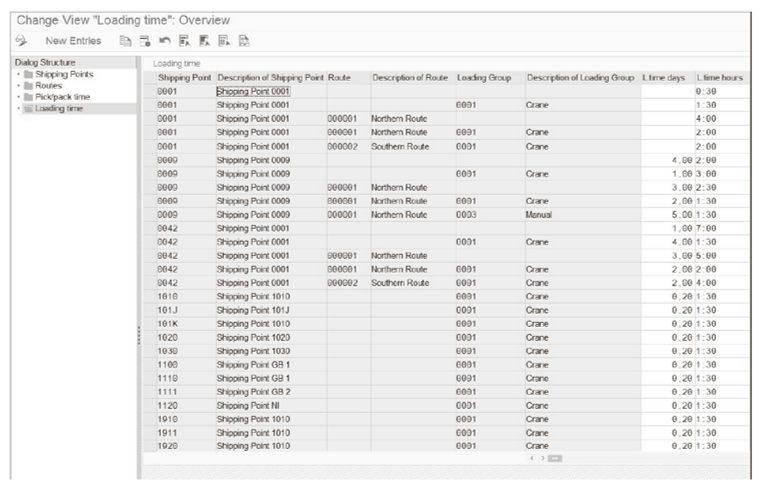

The lead times can be route dependent or independent. Route-independent lead times are maintained on the shipping point. The delivery lead time durations can be maintained in Customizing via SAP IMG > Logistics Execution > Shipping > Basic Shipping Functions > Scheduling > Delivery Scheduling and Transportation Scheduling > Maintain Durations (see the figure below). Here, you can choose to have a static duration for loading and pick/pack activities for a shipping point, or you can have the durations dependent on the route.

Route-dependent durations are maintained separately where the transit durations (first figure), pick/pack durations (second figure), and loading time (third figure) can be maintained for a route.

Factory Calendar and Working Hours

The route determines the itinerary and the means of transport used for shipping the product. This has a direct impact on transportation scheduling. Transport can occur via railway, road, or air, and the lead times could differ. For example, reserving a freight carriage would entail a longer lead time than air cargo. There is also a need to abide by the schedules of the various means of transport, for example, the flight schedule. Together with the route determination, different calendars and time streams are used in scheduling. The calendar indicates the working days, and the working hours can be maintained in shifts. The following calendar and working hours impact the corresponding dates:

- The calendar and goods receiving hours of the unloading point of the ship-to party are used to adjust the delivery date.

- The calendar of the transportation route is used to adjust the goods issue date.

- The factory calendar and working hours of the shipping point are used to adjust the dates for loading and picking/packing.

- The goods issue day and time of the route schedule are used to adjust the goods issue date.

The working hours and durations can be maintained in Customizing via SAP IMG > Logistics Execution > Shipping > Scheduling > Delivery Scheduling and Transportation Scheduling > Maintain Working Hours.

The working days from the calendar and the working hours from the shift are considered in scheduling to ensure no activity is scheduled during nonworking times.

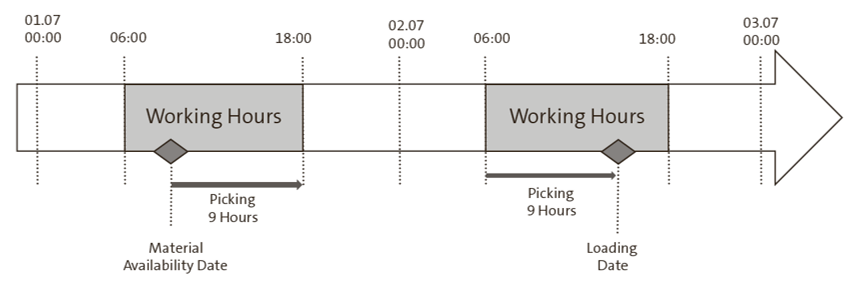

Example: Working Hours. Below shows an example schedule of the following working hours:

- Material availability date: 01.07 09:00:00

- Picking duration: 18 hours

- Working hours: 06:00 to 18:00

- Loading date: 02.07 16:00:00

The scheduling ensures that the dates are aligned according to the factory calendar and working hours. Therefore, forward scheduling could shift dates into the future to respect the working times. In these cases, a pull optimization is done wherein the previously calculated dates are pulled along with the shifted dates to keep the durations between the earliest and latest dates as short as possible.

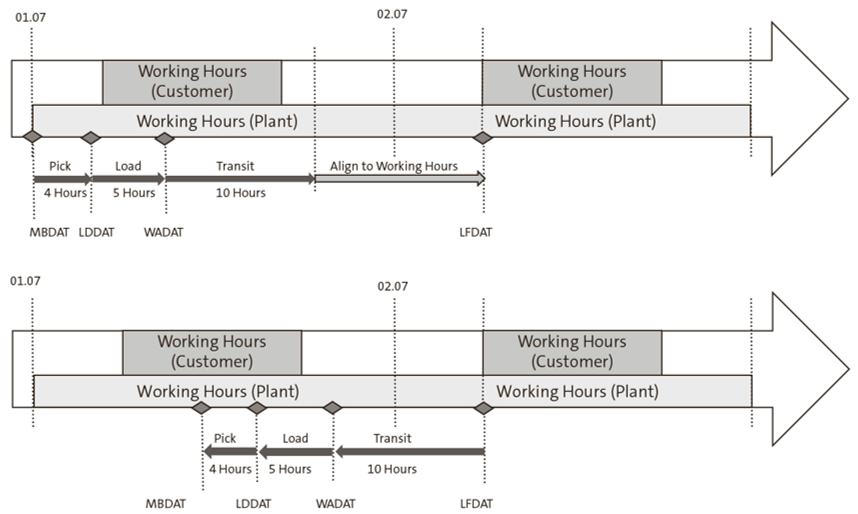

Example: Pull Optimization. The last figure shows an example of pull optimization with the following stats:

- Material availability date: 01.07 00:00:00

- Picking duration: 4 hours

- Loading duration: 5 hours

- Transit duration: 10 hours

- Delivery date: 02.07 06:00:00 (aligned to calendar of ship-to party)

- Pull optimizing: used to backward schedule other dates

- Goods issue date: 01.07 20:00:00

- Loading date: 01.07 15:00:00

- Material availability date: 01.07 11:00:00

Learn Transportation Planning in Our Upcoming Rheinwerk Course!

Get the most out of your SAP TM system! Unlock the intricacies of transportation planning logic, system behavior, configuration levers, and best practices for real-world logistics operations. True planning proficiency is within reach—and with this course, SAP TM mastermind Anton Karnaukhov hands you the keys. Click on the banner below to learn more and order your ticket.

Editor’s note: This post has been adapted from a section of the book Available-to-Promise with SAP S/4HANA by Sujeet Acharya, Sandeep Mandhana, and Jibi Joseph Vadakayil.

Comments