Catch weight means “approximate weight” and is a term which is mostly used in the food industry. If you’re looking to learn how to utilize this in an SAP context, read on.

You can keep track of catch weight in SAP Extended Warehouse Management (EWM) to store stocks of two independent units of measure in a warehouse: one for stock keeping and one for selling (weighing and invoicing). For example, cheese packets can come in two units of measure—pieces and grams. The approximate weight of each pack of cheese might be 200 grams while the actual weight of each packet varies; one pack might weigh 182 grams while the other weighs 196 grams. Thus, each pack of cheese is sold at a different price due to its different weight.

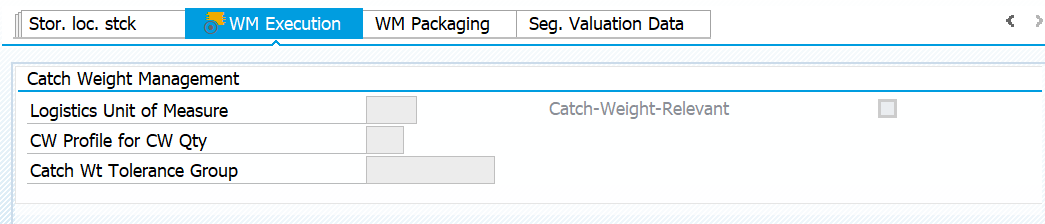

To utilize catch weight management in SAP EWM, you can activate it in the WM Execution view of the material master as shown below.

With catch weight management enabled, let’s take a look at some of its most important parts.

Logistics Unit of Measure

The logistics unit of measure is used for catch weight management. For example, the cheese packs are stocked in pieces but sold in catch weight, which means each pack is weighed and invoiced as per its individual weight. The system doesn’t allow you to manually assign logistics unit of measure. When a unit of measure is marked as a parallel unit, then the system sets the catch unit of measure automatically.

Catch Weight Profile for Catch Weight Quantity

The catch weight profile can be maintained in customization and assigned to the material master to control the input of catch weight quantity. The catch weight quantity can be controlled at the work center level or goods movement (goods receipt/goods issue).

Catch Weight Tolerance Group

A catch weight tolerance group can be defined in customization and assigned in the material master to check if the catch weight falls in a permissible tolerance range. When posting the goods receipt document, the system will check the catch weight of the material and if the checked weight exceeds or falls below tolerance limits, then the system issues an error or warning message. For example, the check weight of one pack of mozzarella cheese can be maintained as 200 grams with a tolerance of 10%. If the weight of the material produced is 170 grams or 225 grams, then the system wouldn’t allow it to post a goods receipt and issue an error message.

Conclusion

For manufacturers that produce a product that can vary in weight, such as those involved in the food industry, it’s important to keep track of each individual output to bill the correct amount. Catch weight management is a system designed to help businesses do just that. This post introduced you to catch weight management with SAP EWM.

This post was originally published 8/2021.

Comments