In a day and age where businesses are working to avoid incurring large inventory costs, testing market sentiment before committing to buying and storing sizeable inventories is an attractive prospect.

A vendor consignment strategy can help businesses streamline their supply chain process and provide a wide variety of goods for customers to select (and thus increase cash flow.) This blog post will give you a comprehensive view of how the vendor consignment process can be beneficial and effective.

What Is Consignment?

Consignment is a business agreement between a retailer and vendor that allows the retailer to pay for a vendor’s products only after the products have been sold. Here, the vendor allows inventory to be kept at a retailer’s location, but they hold the ownership rights.

The vendor remains the legal owner of the material until either A) the retailer withdraws its in-house use of the material, or B) sells the material to an end customer. The invoice payment to the vendor is then due as per the consignment agreement.

Advantages of Vendor Consignment for Vendors and Retailers

There are a number of advantages that make vendor consignment lucrative for both vendors and retailers.

First, the vendor can avoid paying for inventory carrying costs. Once manufactured, the vendor will ship the material to a retailer. Thus, there is more space for the vendor to produce even more stock.

Secondly, it provides for an efficient supply chain. Customers can get materials in real time instead of placing an order that needs to flow from vendor to retailer to customer. This can help in relation to the third benefit: increased cash flow. Selling material in real time increases the cash flow as more orders come in to replace exiting stock.

Lastly, vendor consignment provides better product visibility and customer experience. Since there is no need for customers to wait for the product to be delivered to the retailer, they can get fast delivery.

Disadvantages for Vendors and Retailers

There are also a few disadvantages to vendor consignment.

For one, vendors won’t know how much stock lives at a retailer’s location since they don’t have the materials in hand. The retailer would need to inform the vendor that they need more stock.

Secondly, with the way vendor consignment terms are written, retailers often have to pay more for the stock since they’re not the official owner of the material despite it being held on their property.

For inventory management based on shelf life, vendor consignment can lead to challenges.

Vendor Consignment with SAP

With an introduction to vendor consignment in hand, let’s take a look at setting up and managing vendor consignment stock with SAP.

There are a few prerequisites to get out of the way first:

- For master data:

- Create a Consigned Purchase Info record.

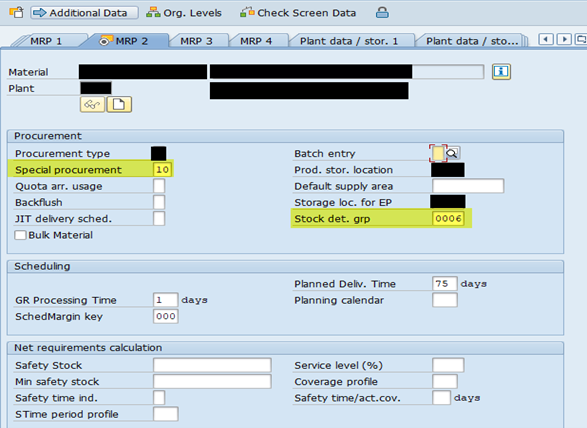

- Update MRP2 view with special procurement type “10” – consigned.

- Update MRP2 view of the material master with stock determination rule

- For configuration:

- Create a stock determination rule for the plant from where vendor consigned inventory is going to be shipped.

- Update the delivery item category with a stock determination rule.

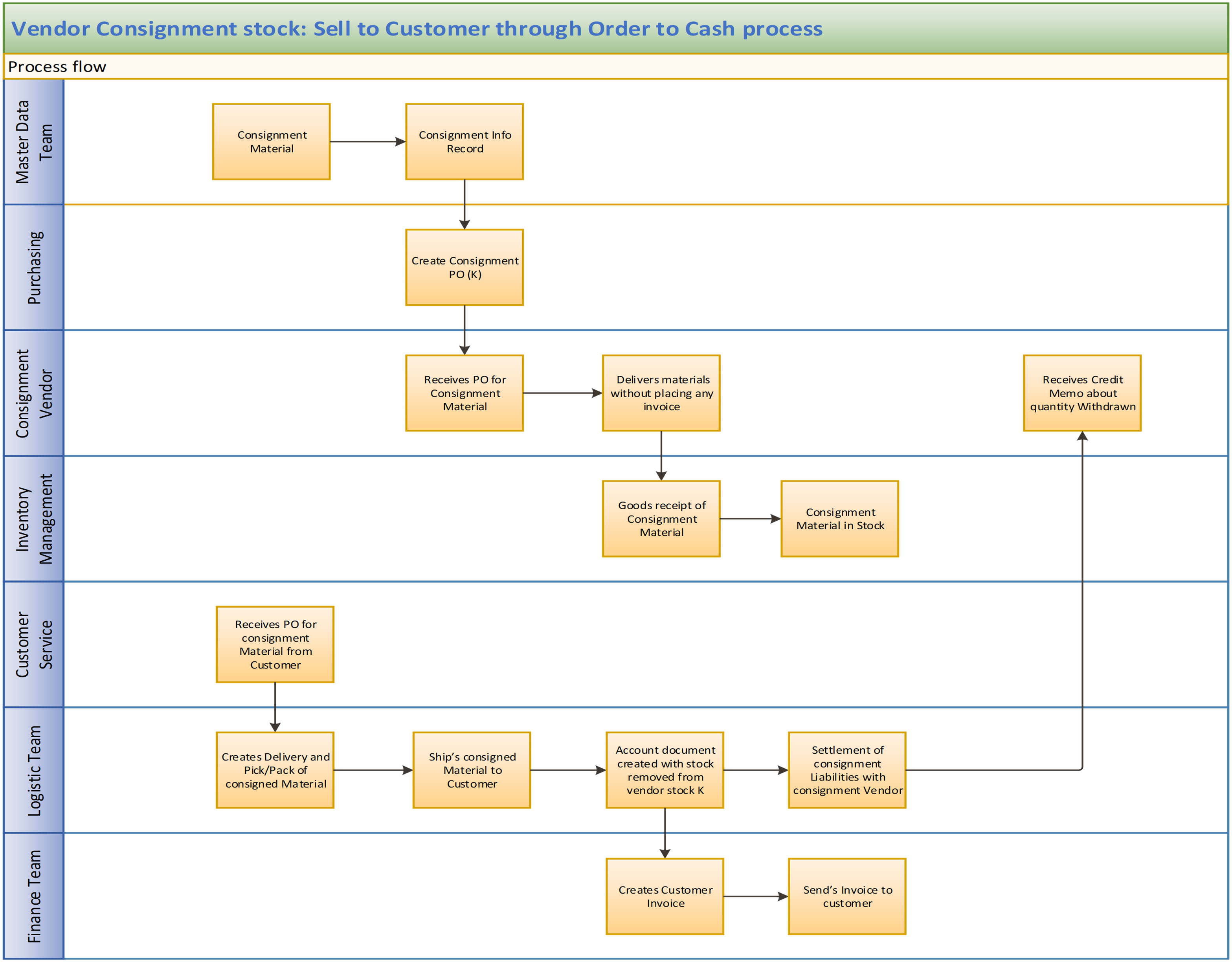

This is the process to follow. We’ll get into more depth on each later in the post.

- Create a purchase requisition manually, or MRP will create a purchase requisition with item category K.

- Create a purchase order with or without reference to the purchase requisition, using Transaction ME21N with item category K.

- Execute Transaction MIGO to complete the goods receipt with reference to the PO. Upon completion of goods receipt, the stock will be placed in vendor-consigned stock with special stock indicator "K"

- Create a sales order with the consigned material and item category, configured with the stock determination rule.

- Create a delivery with reference to the sales order and PGI.

- The stock will then be deducted from the vendor consigned stock with movement type 601-K.

- Create a customer invoice with an accounting document created for accounts receivable.

- Clear vendor liabilities by using Transaction MRKO.

- Send an email to the vendor to inform them about incoming payment (accounts payable).

Configuration

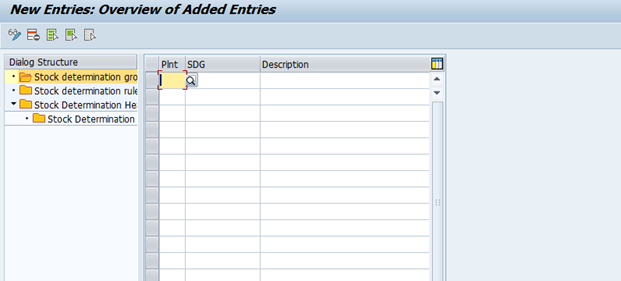

To create a stock determination rule for the plant from where vendor consigned inventory is going to be shipped, follow this menu path: SPRO > Materials Management > Inventory Management and Physical Inventory > Stock Determination > Stock Determination Group > New Entries. Enter the plant and stock determination group.

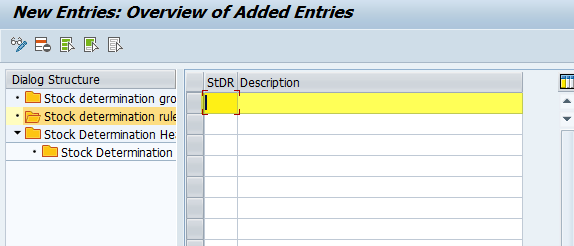

Next, follow this menu path to enter the stock determination rule and description: SPRO > Materials Management > Inventory Management and Physical Inventory > Stock Determination > Stock Determination Rule > New Entry. Enter the four-digit stock determination rule and description.

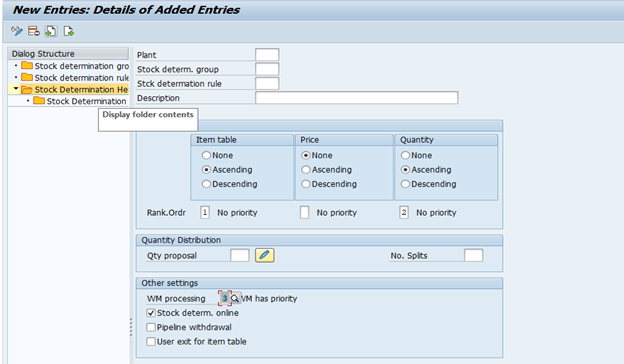

Next, you’ll need to add the stock determination group and rule created in the previous steps with a description. Follow this path: SPRO > Materials Management > Inventory Management and Physical Inventory > Stock Determination > Stock Determination Header Table > New Entries.

The following figure will show you options for helping to create some default settings. To change the sorting options, select the appropriate radio button per your business requirement. To change the rank order, provide priority to sorting as per your business requirement. To change other settings, there are buttons to toggle on or off. For example, we’ve enabled the stock determination, and set WM processing to 3. These, of course, all depend on your unique business requirements, so make changes as necessary. For additional help on any of these three items, you can click “F4.”

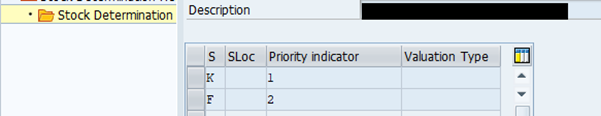

Next, follow the path SPRO > Materials Management > Inventory Management and Physical Inventory > Stock Determination > Stock Determination Header Table > New Entries. Enter the plant, stock determination group, and stock determination rule created in the previous steps by using Description > Stock Determination Item Table.

Based on your business rules, make sure to give priority if your own stock or vendor consigned stock is to be delivered to the customer first.

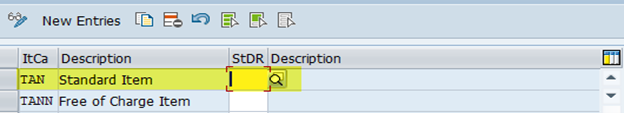

To assign the stock determination rule to delivery item category, follow this path: SPRO > Materials Management > Inventory Management and Physical Inventory > Stock Determination > Assign Stock Determination Rule in the Applications > Delivery > Select Item. Assign the stock determination rule created earlier.

Master Data

Before you can order consignment material as a vendor or post a goods receipt into consignment stock, your business must maintain the price of the material for the vendor in a purchasing info record. The price is necessary for the valuation and settlement of material withdrawals. If you procure consignment material from several vendors, you must create a consignment info record for each vendor. The consignment stock is managed separately for each vendor.

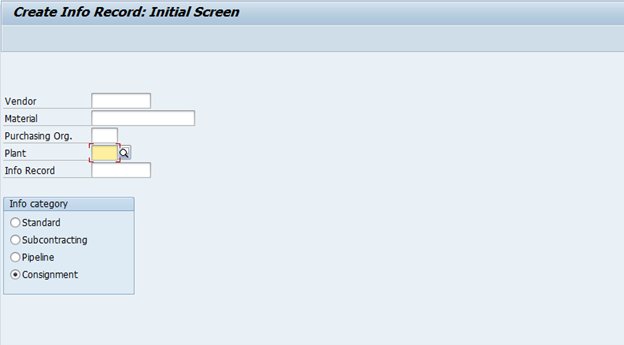

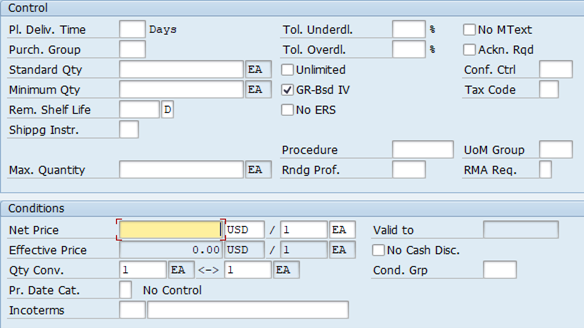

To create the info record, follow this path: Logistics > Materials Management > Purchasing > Master Data > Info Record > ME11 – Create. Enter the vendor, material, plant, and the standard purchasing organization of the plant. Choose the consignment infotype.

Further data maintenance corresponds with that of a normal purchasing info record.

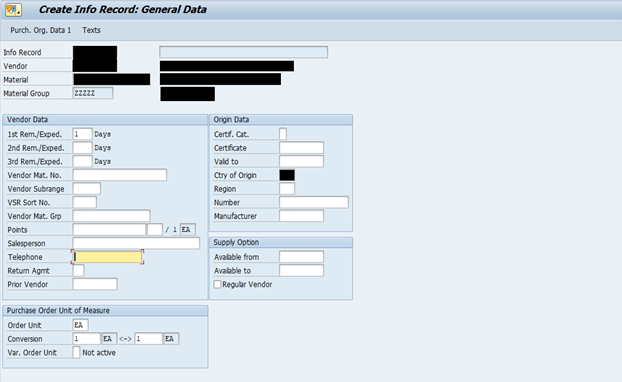

Enter information on the General Data window as shown below.

Enter the pertinent information and save.

Consignment prices can be determined in foreign currency, period-based, and in any unit of measure. You can also take advantage of the purchasing condition technique, including the definition of discounts and price/quantity scales.

Update the MRP2 view with special procurement type “10” – consigned and stock determination group. By using T-code MM02 à MRP2.

Transactions

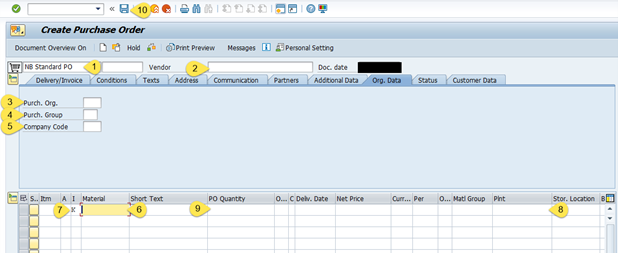

To create a purchase order with or without reference to the purchase requisition through transaction ME21N with item category K, follow this path: Logistics > Materials Management > Purchasing > Purchase Order > Create > ME21N - Vendor/Supplying Plant Known. Enter the following (see the callouts on the figure below to see where to find them on the screen):

- PO type as “NB” standard PO

- Consigned Vendor

- Purchasing org

- Purchasing group

- Company code

- Material

- Item category as K – Consigned

- Plant

- PO Quantity

- Save

To determine that a material is procured for a consignment vendor, enter the item category K (Consignment) in a purchase order. Keep in mind the following:

- You must enter a material number.

- You cannot enter a purchase order price or conditions for the item.

- You require a goods receipt for the item. The goods receipt is posted in the vendor consignment stock and is non-valuated.

- You cannot enter an invoice for the consignment item. Item category K can also be used in outline agreements and purchase requisitions.

If a material is always procured from a vendor as consigned inventory, then the business can consider using a special procurement key in the material master record for MRP. This special procurement key means that a purchase requisition with item category K is created during the planning run for a demand for this material.

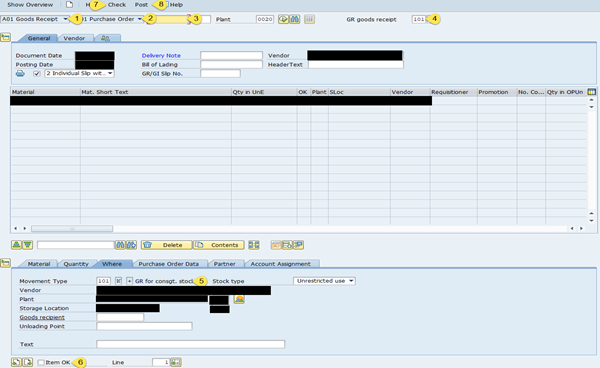

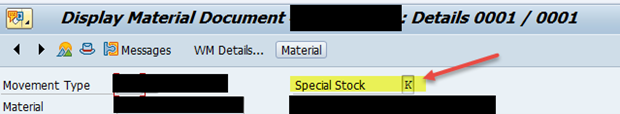

Execute Transaction MIGO to complete the goods receipt with reference to the PO. Upon completion of goods receipt, the stock will be placed in vendor-consigned stock with special stock indicator "K.” To do this, follow this path: Logistics > Materials Management > Inventory Management > Inventory Management > MIGO - Goods Movement (MIGO). Do the following (see the callouts on the figure below to see where to find them on the screen):

- Select goods receipt A01

- Select purchase order R01

- Enter the purchase order to be received

- The goods movement type defaults to 101

- Movement type at item level will come up as 101-K

- Click on OK

- Check the transaction

- Post

Vendor Consignment in Inventory Management: Inventory management supports the following functions within vendor consignment:

- Special stock type of vendor consignment

- Goods receipt in vendor consignment stock with and without reference to a purchase order

- Transfer postings within the vendor consignment stock and transfer postings from vendor consignment stock to your own stock

- Goods issues from vendor consignment stock

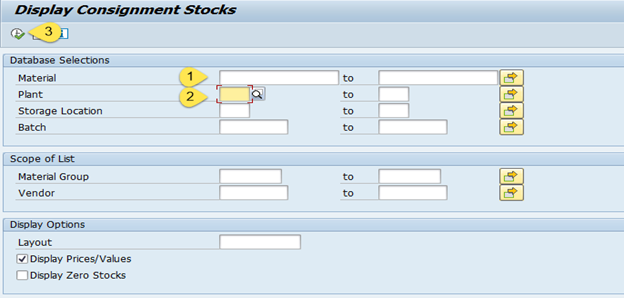

To check vendor consigned inventory in the plant storage location, follow this path: Logistics > Inventory Management > Environment > Consignment > Consignment from Vendor > Stock. You can also use T-code MB54. Do the following (see the callouts on the figure below to see where to find them on the screen):

- Enter the material

- Enter the plant

- Execute

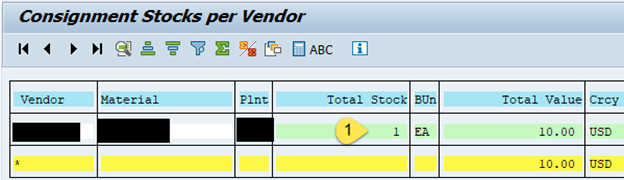

You’ll see the quantity of 1 in total stock, as shown below.

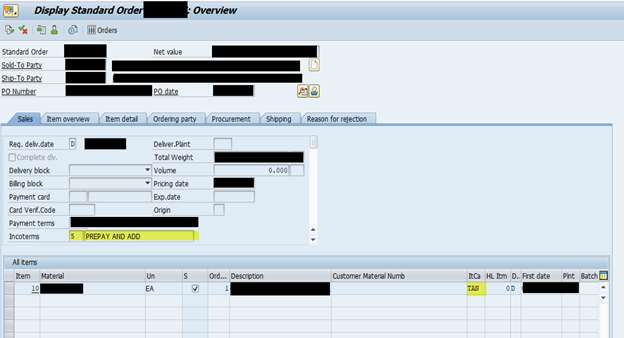

To create a sales order with consigned material and delivery item category configured with stock determination rule, follow this path: Logistics > Sales and Distribution > Sales > Order > VA01 – Create. The item category is TAN - Standard item category.

To create a delivery with reference to the sales order and PGI, follow this path: Logistics > Logistics Execution > Outbound Process > Goods Issue for Outbound Delivery > Outbound Delivery > Create > Single Document > VL01N - With Reference to Sales Order.

The delivery will be created through VL01N or VL04, and then saved. The warehouse clerk will pick and pack goods as they normally do will then perform the post goods issue.

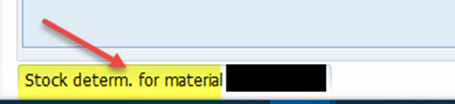

During post goods issue, the message shown below will appear. This means the system is picking vendor consigned material to complete post goods issue.

Stock will then be deducted from the vendor-consigned stock with movement type 601-K. The material accounting document will be created that shows this movement type and special stock indicator.

The consigned stock will be checked via Transaction MB54 for plant and material combination. No stock exists for specified data.

Next, create a customer invoice with an accounting document created for accounts receivable by following this path: Logistics > Sales and Distribution > Billing > Billing Document > VF01 – Create with reference to Delivery. Once this occurs, an invoice is created successfully and posted to accounting for accounts receivable.

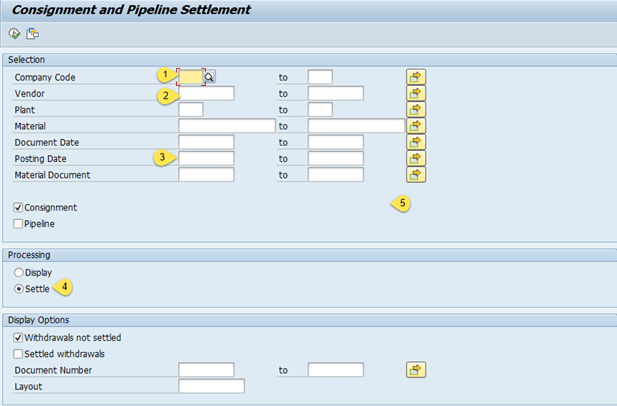

The business should regularly clear liabilities towards the vendor that exist. Clear them with Transaction MKRO. Keep in mind the following:

- The consignment goods are settled without invoice receipt, as the vendor cannot trace the goods withdrawal directly.

- The vendor can only manage the consignment stock to settle consignment withdrawals.

- With this report, businesses can display settled and non-settled consignment withdrawals.

- Possible selection criteria include:

- Company code

- Plant

- Vendor

- Material

- Document date

- Posting date of the withdrawal

- Material document number

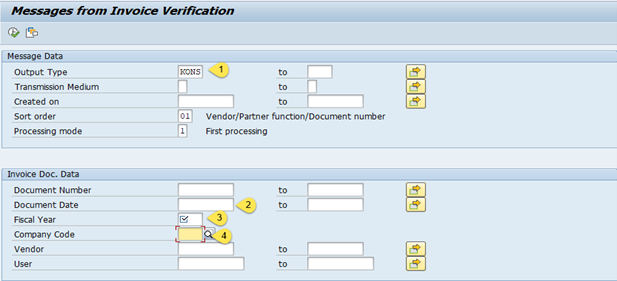

Businesses can inform the vendor about the settled withdrawals and the credit memo amount. SAP creates a message with message type KONS in addition to the settlement document, which can be sent as an email to the vendor.

Do the following with Transaction MRK0 (see the callouts on the figure below to see where to find them on the screen):

- Enter the company code.

- Add the vendor number for the consigned vendor

- Add the posting date

- Settle the transaction

- Execute

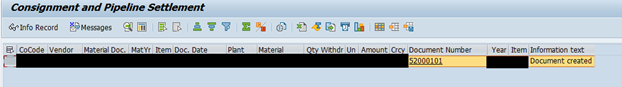

A document number will be created, which we can check in FB03. We want it to read “document created.”

The vendor is billed as per the price in the consigned purchase info record. Goods are consumed based on standard price and the difference between purchase info record price and standard price appears as PPV.

To send an email to vendors informing them about incoming payment, use Transaction MR91. Specify the following (see the callouts on the figure below to see where to find them on the screen):

- Output type

- Document date

- Fiscal year

- Company code

You should not expect an invoice from the vendor for goods withdrawals from consignment stocks or a pipeline. Instead, you settle posted withdrawals and return deliveries yourself and send the vendor a statement of the settlement. You can perform this settlement periodically in the background. The following documents can be involved:

- Invoices

- Credit memos

Consignment settlement is connected to message determination. As a result, you can define a form in Customizing. A message record is created during each settlement. This message record completes the form. Depending on the system settings, you can send this form to the vendor immediately upon posting or at a later time.

Conclusion

The vendor consignment process in SAP involving both the materials management and sales and distribution modules is a powerful process for both retailer and vendor by giving both advantages. Thank you for reading and stay safe!

This post was originally published 6/2023.

Comments